Supply Chain Risk Management

The term “supply chain” refers to the network between a company and its suppliers to produce and distribute a specific product, and the steps involved in getting the product or service to the customer. In any industry, a number of risks may occur at any point in the supply chain, which may result in harm to not only the product or service but the workers involved.

Supply chain risk management is a means of monitoring the likelihood and consequence of events at any point in the chain. This begins with sourcing raw materials and continues through to the end use of customers. Management involves coordinating activities to direct and control a company’s end-to-end supply chain with regard to supply-chain risks.

Supply chain risk management is a means of monitoring the likelihood and consequence of events at any point in the chain. This begins with sourcing raw materials and continues through to the end use of customers. Management involves coordinating activities to direct and control a company’s end-to-end supply chain with regard to supply-chain risks.

Effective supply chain risk management (SCRM) is highly important to the success of a business. essential to a successful business. SCM is constantly evolving, as new measures must be applied to new threats in the workplace.

Supply Chain Risk Management includes:

- Assessment of both internal and external environments

- Identification of risks

- Assessment of level of risk

- Treatment of risks

- Vigorous monitoring and review of risks

How Does Supply Chain Risk Management Work?

Managing risks begins with the implementation of strategies. These are based on the principles and standards that must be adhered to within an industry.

The process begins with identifying internal and external environments. Prioritizing and addressing risks requires a company to identify criteria for determining what constitutes a ‘risk’ in its operations. Once this is established, the company can undertake risk identification and assessment. This involves risk identification, risk analysis, and risk evaluation.

Risk identification generally entails listing common risks, such as:

- External: natural disasters, accidents, sabotage, labor shortage

- Supplier risks: Production issues, financial problems, subcontractor problems

- Distribution risks: Cargo damage, warehouse inadequacies, supply pipeline constrictions

- Internal risks: Personnel availability or facility unavailability.

Once identified, risks may be prioritized in terms of their likelihood of occurring and consequence they can pose to a company’s operations.

The company can then devise risk treatment plans. This involves taking measures to protect the supply chain from risks, action plans to respond to events caused by risks, and strategies to continue operations in the face of disruptions.

Implementing supply chain risk management requires continual communication and consultation as well as monitoring and review. Maintaining a supply chain risk management plan involves evaluating the effects of risk treatment as well as responding to changes in suppliers, processes, and regulation affecting elements of the supply chain.

Most importantly, a risk management plan should allow for identifying opportunities for improvement.

Why is Supply Chain Risk Management Necessary?

The overall objective of supply chain risk management is to minimize harm in the workplace. In all regulated industries, risks must be continuously managed in order to ensure the safety of workers, consumers and all others in the workplace.

The overall objective of supply chain risk management is to minimize harm in the workplace. In all regulated industries, risks must be continuously managed in order to ensure the safety of workers, consumers and all others in the workplace.

Supply chain risk management is also an essential element of preparing for the unexpected. Even small problems can snowball into issues that can ruin a company. It’s vital that a company plans for these disruptions and has the tools in place to restore order.

Risk management is, essentially, the lifeblood of the company. Strategies employed to monitor and minimize risk will protect the business and reduce the chance of disaster. Improper risk management can result in financial loss, a damaged reputation or even closure.

Tools For Implementing Supply Chain Risk Management

A comprehensive risk management system should comprise of different equipment specifically designed to monitor and minimise risk. Monitoring solutions in the form of impact and temperature monitors are crucial for gauging the conditions of operating equipment. A variety of tools can be used to record and document changes in a working environment and provide alerts to potential threats.

Impact Monitoring

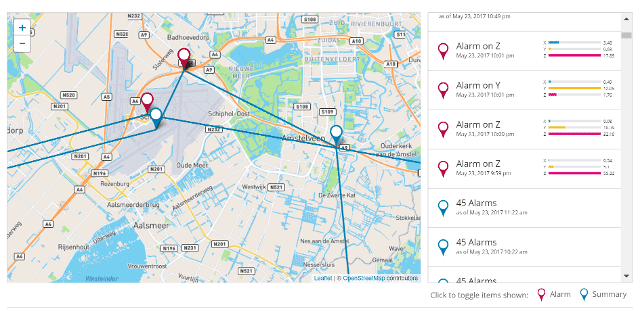

Impact monitors are designed to record various events that occur during operation, and the magnitude of each impact. They include a GPS to locate the site of the event.

Temperature Monitors

Temperature monitors gauge variations in operation function and record unusual movements, along with the extent and duration of any anomaly.

Software

Cloud solution software provides an aggregation of trip data in real-time. Data is presented in graphs in an easy-to-read format, and includes location of impacts, impacts over time, histogram, and temperature. Visualizations for multiple units are provided.

Supply Chain Risk Management: The Big Picture

The importance of keeping risks in check is not to be underestimated. Problems can and do occur, and the consequences may be catastrophic to a company.

Effective supply chain risk management requires time, planning and the right tools. A strategic risk management system is essential for a comprehensive picture of the entire supply chain, providing the details required to identify and mitigate risks.

Visit our blog to learn more about the ways our products can optimize your business needs!