MAG 2000 Freight Shipping Shock Indicator

The ShockWatch MAG 2000 impact indicator is a cost-effective, resettable and reusable device designed to monitor the handling of fragile goods and freight containers greater than 500 lbs. The device is also widely used on rail cars and trucking fleets to monitor for excessive impacts during humping or latching.

The MAG 2000 utilizes two tuned and highly sensitive magnets. When an out-of-tolerance impact is experienced, the magnets are forced out of alignment clearly indicating the angle and severity of impact. A uniquely designed key is supplied to unlock the cover on the unit. This key allows the product to be reset after activation and resists tampering.

Read More

Empower Logistics Visibility with Shipping Damage Indicators

Heavy freight needs more oversight than a typical impact indicator can deliver. Whether you’re shipping architectural glass, electrical transformers, autos, medical imagers, drilling equipment, or other heavy cargo, if it could be damaged by impacts, it needs monitoring.

On the outside, heavy equipment may seem sturdy, but internal components and structures can be damaged by impacts caused by crane accidents, forklift errors, freight car coupling, and even miles of rough roads. If cargo is damaged, it’s better to know about that damage before it is put into service. Knowing your goods experienced conditions that may have caused damage gives you the chance to inspect it before it reaches your customers. That can mean the difference between repairing or replacing equipment – like industrial turbines or transformers – locally versus waiting until it reaches its final, often remote, destination that may be halfway around the world.

Use Impact Labels to Avoid Unplanned Damage and Downtime

Seemingly robust equipment came to be damaged, as easily as sensitive scientific instruments. For example, significant shocks can bend automotive frames and misalign internal components in drilling or other industrial equipment, hastening wear and leading to unplanned maintenance.

Even slight shocks can be enough to snap delicate wiring or break fragile solders deep inside electronics, and can take engineers hours to find and fix the problem. MRI machines are a good example. A shock can break coil loops, damage cables and damage connector pins, and cause solder joints to fail, as well as loosen components so they fail later.

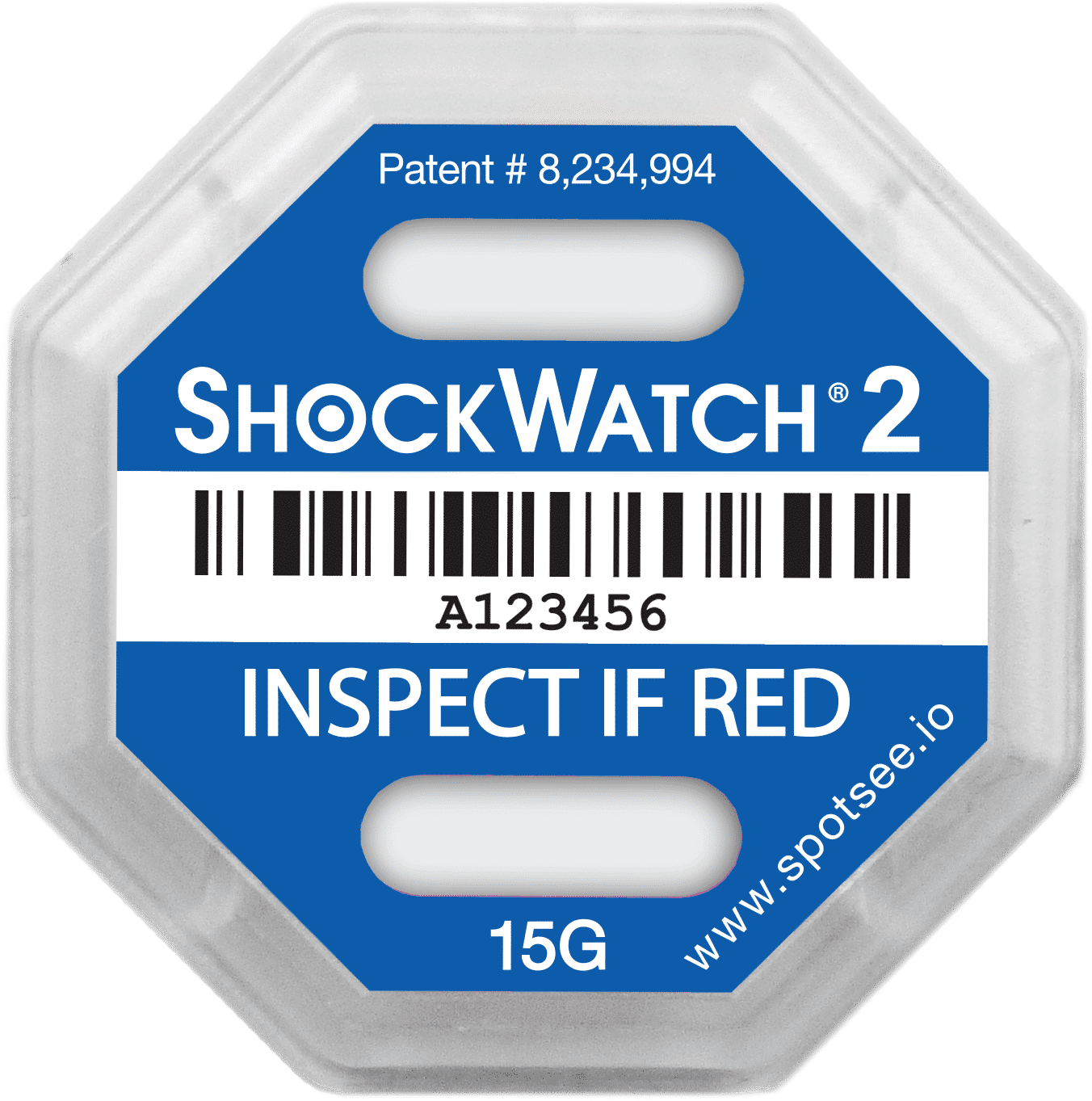

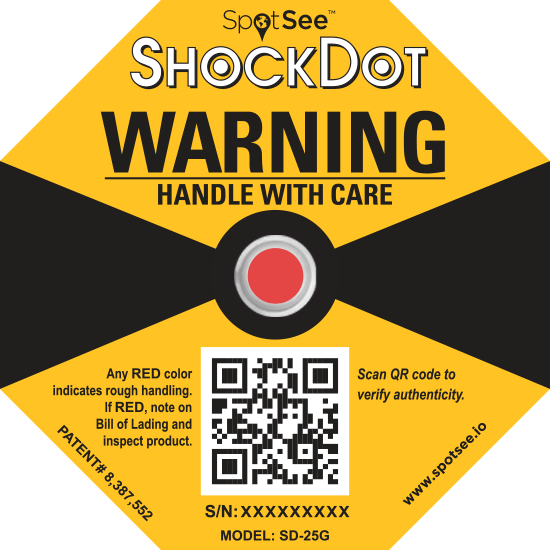

SpotSee’s ShockWatch MAG 2000 impact indicator can help you identify damage before it becomes a problem. This is a cost-effective, reusable shipping damage indicator designed specifically for cargo that weighs 500 pounds or more. It measures shocks in 0.5G increments between 0.5 and 20Gs. To put that into perspective, a hearty slap on the back measures 4.9Gs, and the maximum G-force permitted on turns during the RedBull air races is 10Gs.

The ShockWatch MAG 2000, alone or combined with other shock watch stickers or impact labels, provides visible notice to cargo handlers that this freight is monitored and a robust, reliable solution that helps you minimize damage. And, by providing condition-based insights into logistics operations, this impact indicator helps you to learn exactly how your cargo was treated in transit. As a result, you can mitigate problems now and take actions to prevent similar problems in the future.

For more information about how SpotSee’s impact indicators can minimize supply chain risk, contact SpotSee.

Read Less

MAG 2000 APPLICATIONS

- Auto and Truck Parts

- Electronics – Computer Hardware

- Textiles

- Glass

- Consumer Products

- Construction – Supplies and Fixtures

- Energy and Utilities

- Metal Fabrication

- Railroads

- Consumer Electronics

- Equipment Rental

- Auto and Truck Manufacturers

- Scientific and Technical Instruments

- Biotechnology and Drugs

- Industrial Equipment

- Medical Devices and Supplies

- Logistics / Transport and Storage

- Electronics – Telecommunications

- Aerospace and Defense

- Furniture and Fixtures

Sensitivity Range

0.5 – 20G (in 0.5G increments)

Duration

0.5 – 50 ms

Tolerance

±10%

Operating Temperature

-4°F to 140°F

Shelf Life

2 years

Size

2.5 in x 2.4 in x 0.79 in

Part Numbers

| MAG 2000 Single Unit (“x” is G value desired; 0.5G to 20G) | M21-xG |

| MAG 2000 Single Unit with Adhesive Backing (“x” is G value desired; 0.5G to 20G) | M21A-xG |

| MAG 2000 Single Unit with Bracket (“x” is G value desired; 0.5G to 20G) | M22-xG |

| MAG 2000 Single Unit with Foam Adhesive & Bracket (“x” is G value desired; 0.5G to 20G) | M22A-xG |

| MAG 2000 Two Units with Foam Adhesive & Bracket (specify G value when ordering) | M23A |

Related Documents

Accessories

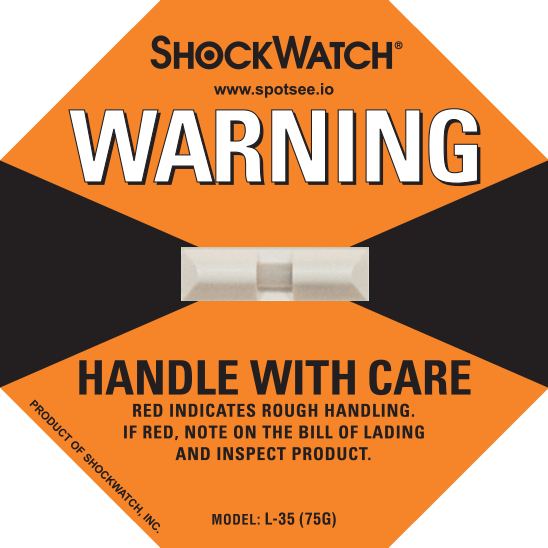

Alert Tape

ShockWatch packing tape provides an unmistakable visual alert that impact indicators are in use and reinforcement that proper handling procedures are required.

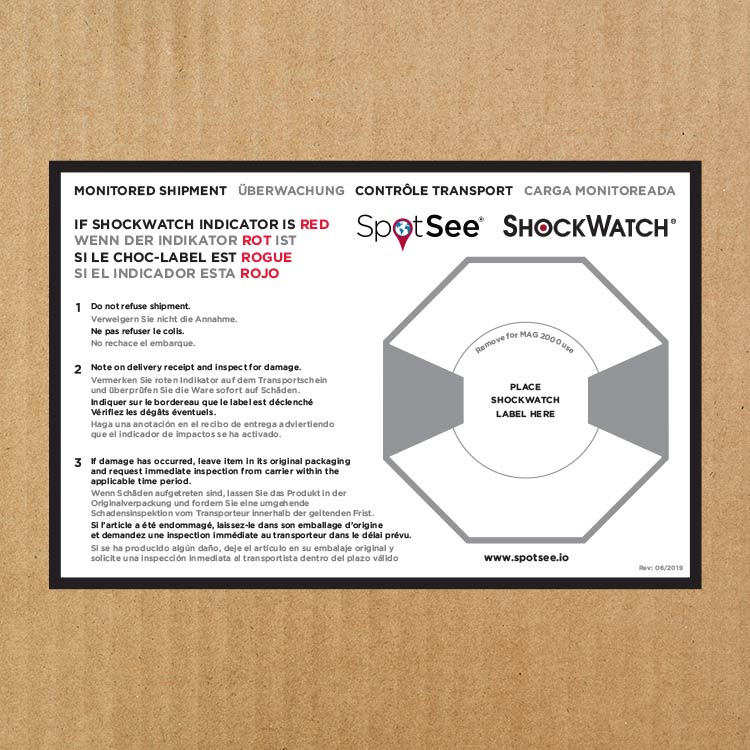

Multi-language Companion Label

A companion label provides a visual warning that the package is being monitored and has instructions on what to do should mishandling occur.