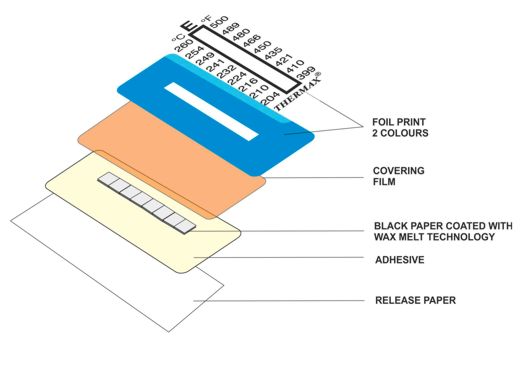

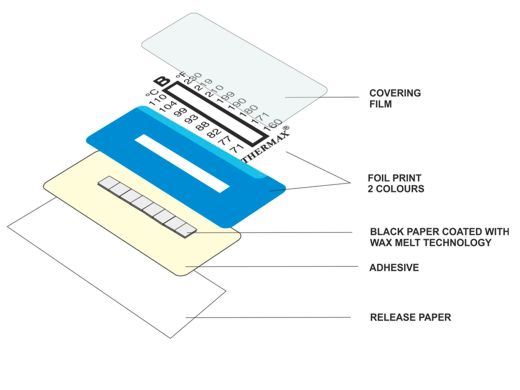

Sharply defined melting points of a purified organic chemical provide unique, high precision temperature sensitive phase change indicators with color change effects. Each temperature element uses a different chemical compound and is made separately by applying a coating containing the chemical to a special absorptive paper substrate. When the rated temperature is exceeded, the chemical melts and is absorbed by the substrate, causing a permanent color change to black.

Offering precise readings, these irreversible temperature labels combine:

- Defined melting points– Giving high accuracy with the ability for you to specify exact requirements based on your needs

- Individually Coated– Allowing you to design your label giving you accurate and clearly defined results

- Permanent Color Change– Allowing you to keep records for quality control and due diligence or records abuse of your products in the field

Irreversible vs Non Reversible Temperature Labels

Both terms describe the same technology. An irreversible or non reversible temperature label permanently records when a specific temperature has been reached. Once the color change occurs, the label cannot return to its original state. The terminology varies across industries, but the function remains identical, providing a permanent visual record of temperature exposure.

In contrast, reversible indicators can change back when temperatures drop, making them useful for continuous monitoring but not for evidence of heat exposure.

How Irreversible Temperature Labels Work

Each SpotSee label contains a purified organic compound that melts at a precise temperature. When that threshold is reached, the compound is absorbed into the substrate and produces a dark color change. This transformation provides a clear, permanent visual signal that the temperature limit has been exceeded. Because every temperature point uses a different compound, the labels deliver reliable and repeatable performance across a wide range of applications.

The technology is based on controlled phase change, not electronics or external power, ensuring consistent accuracy even in demanding environments.

Key Advantages of SpotSee Temperature Labels

- Permanent record of temperature exposure for audits and quality control

• High measurement accuracy based on defined melting points

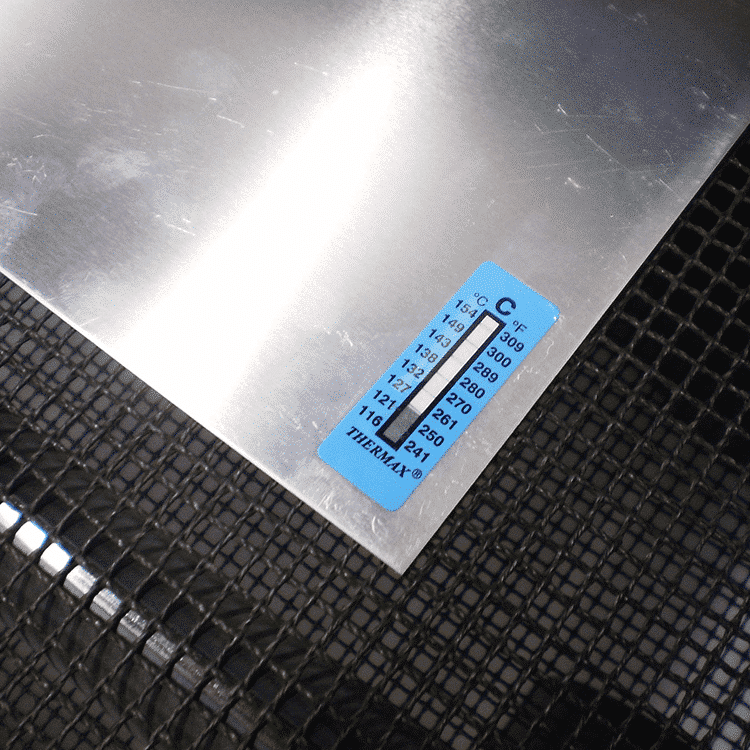

• Immediate visual confirmation without instruments

• Simple to apply on equipment or packaging

• Custom designs available for specific temperature ranges and materials

These benefits make SpotSee temperature labels a dependable choice for safety monitoring, process validation, and product assurance.

IRREVERSIBLE TEMPERATURE LABELS APPLICATIONS

- Process Control – Giving you consistent results

- Test & Measurement – Delivering accurate results

- Quality Control– An affordable solution to safeguard quality

- Safety Indicators– Protecting people, equipment, machinery, and products

- Warranty – Removing the risk of false claims

- Maintenance – Reducing downtime and maximizing performance

Temperature Range

- 29-290°C and 84-554°F

Color Change

- THERMAX Strips containing temperatures only up to

210°C / 410°F – Silver/White to Black - THERMAX Strips containing temperatures of 212°C / 414°F

and above – Orange to Black

Film

- THERMAX Strips containing temperatures only up

to 160°C / 320°F – Polyester - THERMAX Strips containing temperatures between

165 and 210°C / 329 and 410°F – Polyethylene Naphthalate - THERMAX Strips containing temperatures of

212°C / 414°F and above – Polyimide

Available

- Strips can be supplied in packs or rolls – Convenient

and simple to apply - Custom designs – Offering a bespoke solution

- Custom sizes, shapes and materials – Designed

to suit a wide range of application