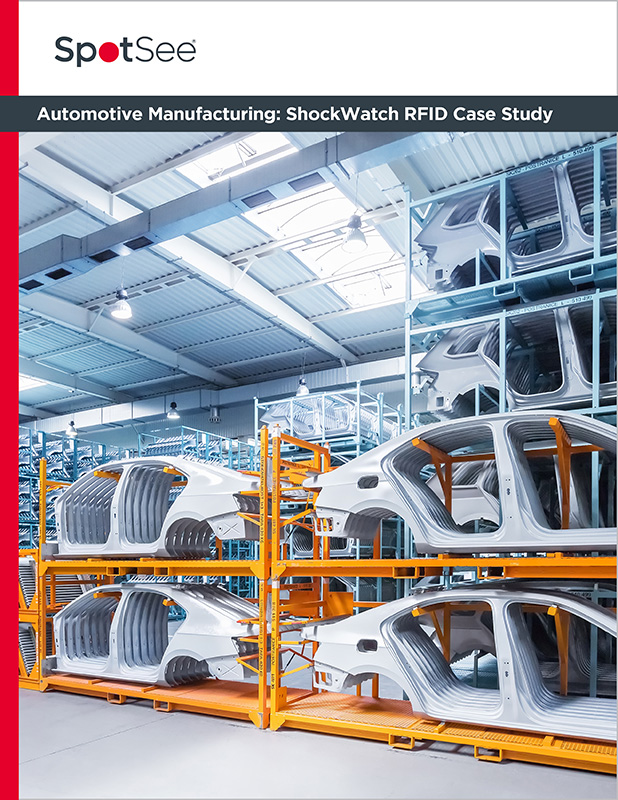

Automotive

Click HereSmart Solutions for Automotive Supply Chain Monitoring

With 30 percent of factories already incorporating RFID, IoT, and other smart technologies, the industry has aggressive plans to convert another 44 percent of its factories in the next few years, according to Capgemini. For logistics managers, the move to smart technologies means deploying monitors to report the conditions and locations of items in the factory as well as during transit.

The need to ensure quality and timely delivery are key drivers. In normal times, condition monitoring helps logistics managers flag components that have experienced impacts and temperature, humidity, and tilt events that could cause damage.

Passive RFID Tags Enable Holistic Automotive Supply Chain Damage Programs

During automotive supply chain disruptions, condition and location monitoring becomes even more important. Consider this: the 2020 global coronavirus outbreak left auto manufacturers throughout the world scrambling to find and purchase components when their usual suppliers shut down. During that time, they had to arrange new logistics lanes and routes, and sometimes even transportation modes and carriers. The usual transit conditions could no longer be assumed. Knowing that components were in transit and that they were undamaged was important.

ShockWatch® RFID tags provide a connected solution that ensures that cargo is scanned automatically at each handoff, even when the passive RFID tags are inside cartons and invisible to handlers. That eliminates human error associated with manually logging items into the inventory management system and the need for warehouse personnel to actually see a tag that signifies damage.

ShockWatch® RFID tags provide a connected solution that ensures that cargo is scanned automatically at each handoff, even when the passive RFID tags are inside cartons and invisible to handlers. That eliminates human error associated with manually logging items into the inventory management system and the need for warehouse personnel to actually see a tag that signifies damage.

ShockWatch RFID impact indicators help streamline inventory management and prevent the use of damaged products. By indicating mishandling that may have caused damage to components being shipped, impact indicators determine if inspection is necessary and helps assign accountability for any damage.

As a recognized solution for supply chain monitoring, carriers treat monitored packages more carefully. As a result, users have reported in-transit damage reduction between 40 and 60 percent.

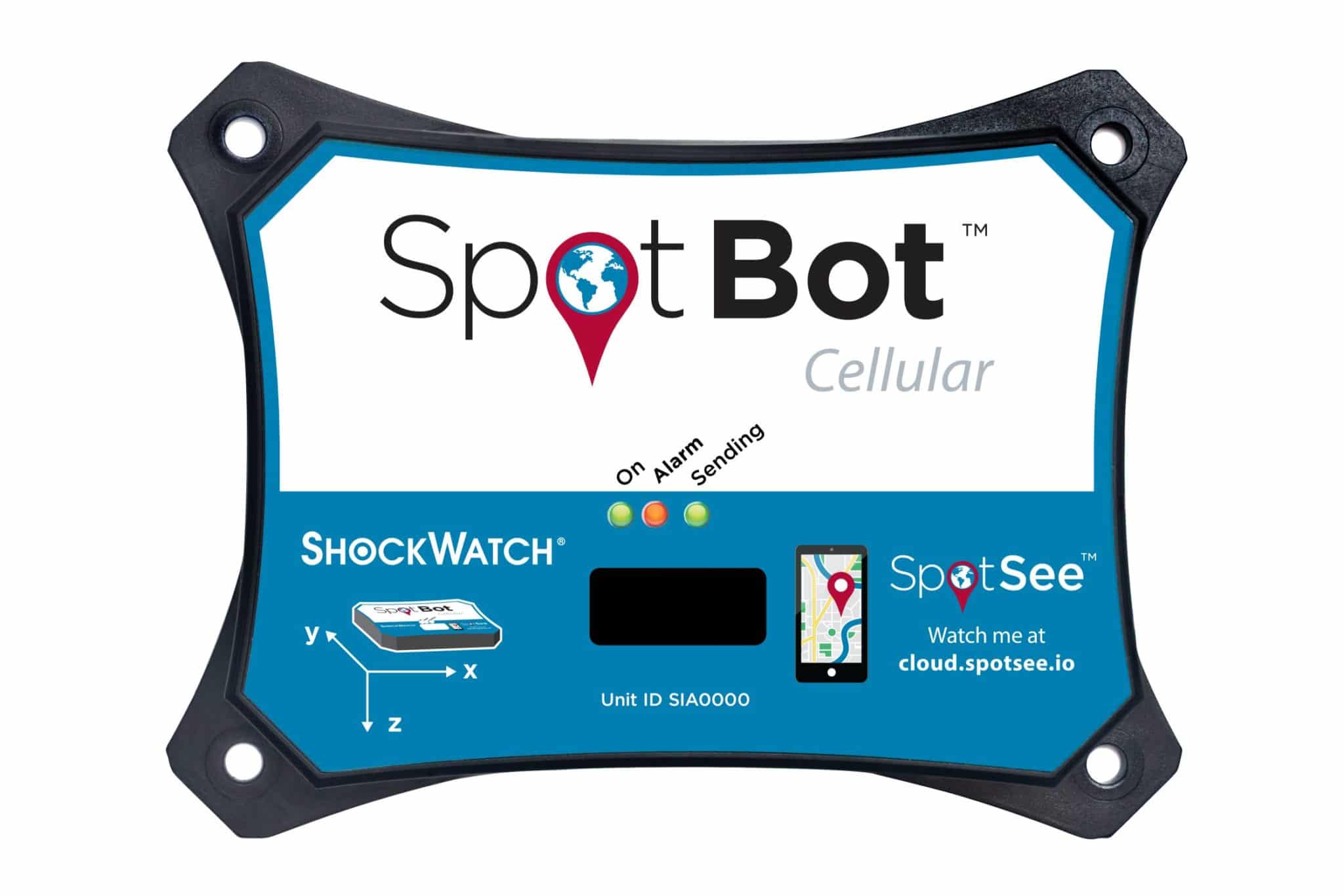

While ShockWatch RFID tags alerts you that an impact occurred, the SpotBot® Cellular continuously monitors impact and temperature during transit and communicates unacceptable conditions and location as they occur.

Knowledge of potential damage prior to arrival allows businesses to proactively make decisions regarding the shipment, which may include sending replacement components to clients even before the original shipment arrives. This ability is a keen competitive edge for suppliers of time-critical goods helping them provide faster, better, service for their internal and external clients.

Condition and location tracking are important for today’s operations and it allows smart companies to develop trend analyses based on historical data: incidents by carrier, lane, route, type of damage, and time of year. The data helps logistics teams spot trends they can use to improve future operations. Using historical data as a baseline, they can cite empirical reasons for the changes they make and measure any improvements.

A comprehensive approach to condition monitoring is a key element in smart manufacturing. ShockWatch RFID and SpotBot Cellular are two of several innovative technologies that provide the detailed information and protection needed by today’s automotive industry.

To learn more about condition monitoring and to find the solutions that are right for you, contact SpotSee®.