Blog

ColdSNAP freeze indicators: Reliable freeze detection for high-value pharmaceutical and medical shipments

When a shipment contains something truly irreplaceable (think biologics, diagnostic materials, or time-critical medical supplies from equipment to transplant organs), “we’ll sort it out later” isn’t an operational option. You need a clear temperature excursion signal...

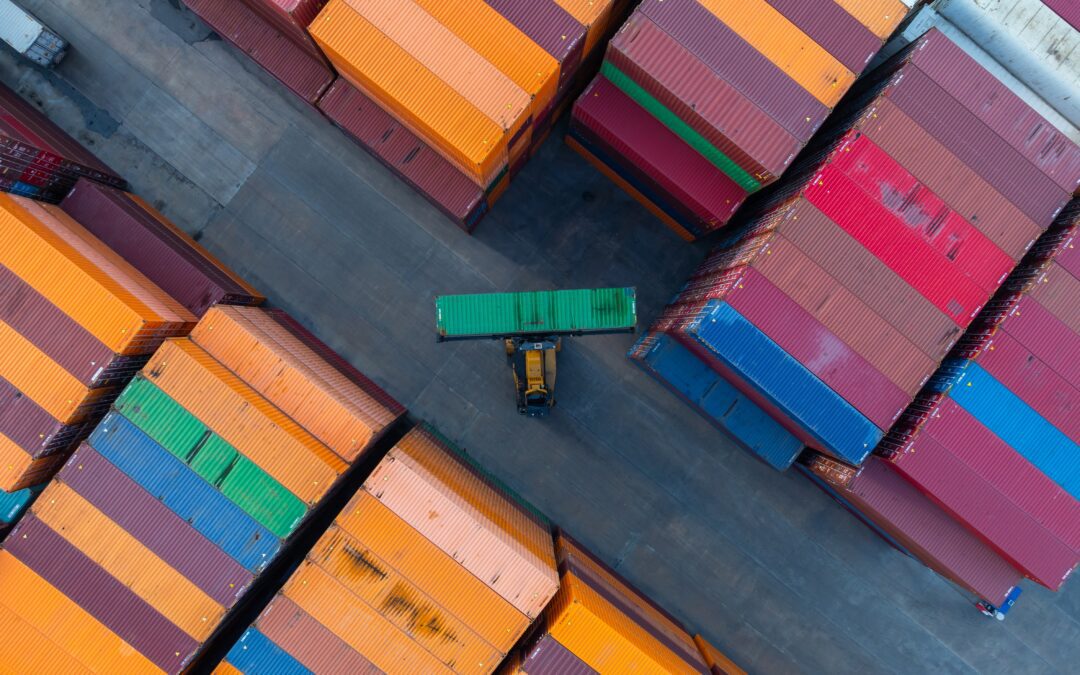

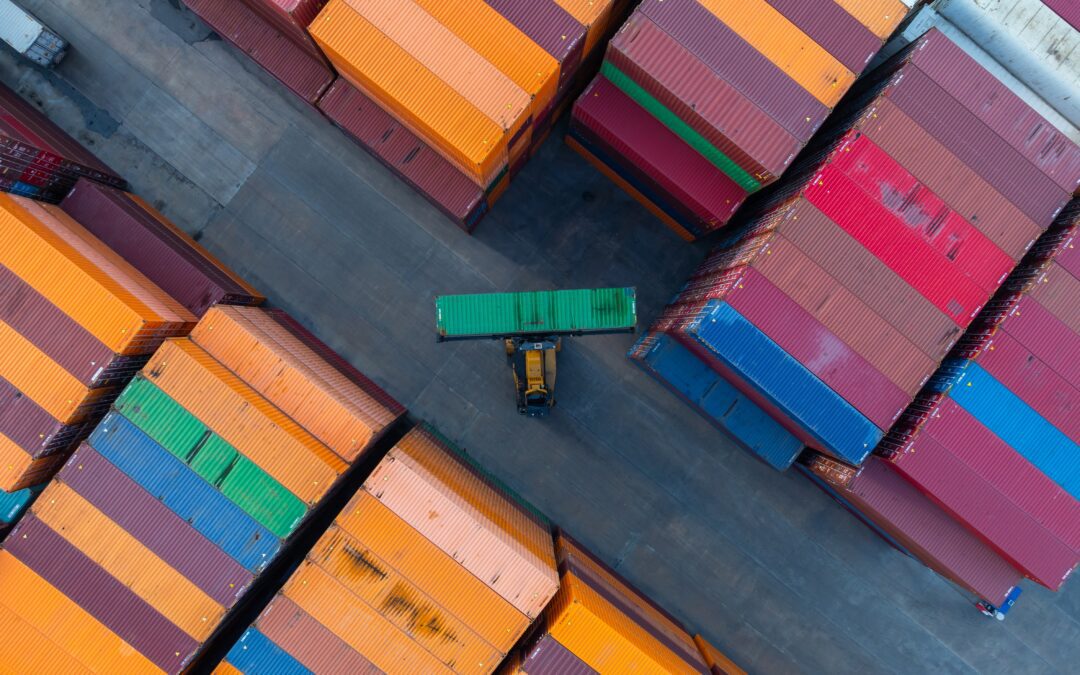

Choosing the right impact monitoring solution for industrial supply chains

You’re evaluating impact monitoring devices for a $75,000 industrial shipment, think a backup generator controller, a high-value pump skid, or a flight-critical avionics subassembly. Sales rep suggests a cellular-connected device. Procurement wants the cheapest...

Temperature sensors or data loggers: Making the right choice for pharmaceutical cold chain shipments

A biologic shipment arrives at your distribution center. Box integrity looks acceptable. Inside, a temperature data logger has recorded the entire journey, but the receiving team can’t access that temperature history without opening the box and downloading the...

HemoTemp II blood bag monitor: Operational clarity for hospital blood banks and pathology labs

When blood bags return from the OR, cold storage staff need a decision they can defend: protect patient safety, conserve a scarce resource, and avoid preventable waste. A surgery team orders eight units of O-negative blood for an emergency trauma case. The team uses...