QUALITY LEATHER MANUFACTURING

Sector: AUTOMOTIVE

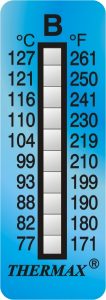

Thermax Irreversible Labels used to monitor temperatures in high quality automotive leather accessories

Project

Throughout the world, automotive manufacturers put their trust in the quality of a leading international leather manufacturer.

Aim

Producing over 40,000 sq metres of high quality automotive leather per day, this company use state of the art production facilities and quality control features to guarantee their consistently high levels of customer satisfaction. Therefore they must ensure that the correct temperatures are reached during the manufacturing process.

Solution

Thermax® 10-Level Range B Strips are used in the process to verify the processing temperatures during the production of the automotive leather. The customer will not disclose the exact nature of the use of the large volume of strips that they buy, due to the proprietary nature of the process, however, we believe it is possibly related to the adhesive used in the process (similar to the glue line temperatures used in the textile industry).