Dialysis Case Study: WarmMark®

Summary: WarmMark thermal indicators are as easy to use as they are to read. The dialysis center simply adds the WarmMark temperature card to the box containing the blood samples and ships it as usual. When the package arrives, lab technicians have visual confirmation showing whether the samples exceeded safe thermal thresholds and, if so, for how long. Then they know what steps to take to protect the integrity of the results.

Product Solution: WarmMark Temperature Indicator Labels and Stickers

Read The Case Study

Dialysis Case Study: WarmMark®

Company Profile

Industry: Medical

Application: WarmMark temperature monitoring

Challenge: Protect the integrity of dialysis center blood samples

WarmMark Helps Protect the Integrity of Dialysis Center Blood Samples

Multiple, regular blood tests lay the foundation for treatments for chronic kidney disease and dialysis. Virtually every treatment decision nephrologists make is guided by results from patients’ recent blood tests. It is imperative, therefore, that test results are accurate.

Ensuring accuracy involves good chemistry in the lab, but it also involves reliable logistics. That means transporting blood samples in thermal packaging to minimize the risk of temperature excursions, and monitoring their internal temperature during transport so lab technicians know whether samples became too hot to be used.

The National Center for Health Statistics reports that 6 million Americans have been diagnosed with chronic kidney disease. Many more have not yet been diagnosed. In 2021, the Centers for Disease Control and Prevention estimated the number of diagnosed and undiagnosed people with chronic kidney disease at 37 million –

1 in 7 Americans. Kidney treatments, therefore, are likely to increase in number.

For those diagnosed with chronic kidney disease, batteries of tests are performed to determine the effectiveness of their current treatment to clear urea and creatinine, to determine urea reduction ratios, and to measure electrolytes, hematocrit and hemoglobin. Some are performed about once each month or a few times per year. For later stage patients, blood tests are performed before and after each dialysis session.

Typically, blood is drawn from patients at local dialysis or healthcare centers, packaged with samples from multiple patients at the end of the day, and shipped overnight to a certified laboratory for processing and analysis. The next day, the test results are emailed to the patients’ physicians, who uses them to adjust their next treatments.

Heat Skews Blood Tests

The tests the lab performs are highly specific and accurate under controlled laboratory conditions. Real world results, however, are more variable. That’s often because of differences in how the samples were handled during transportation. Blood samples, like other medical specimen, can be damaged by heat.

Dialysis centers protect the samples with thermal packaging but, even then, thermal excursions sometimes occur. It’s often the little things that cause the problems – sitting unprotected at the front desk too long while awaiting pick-up, faulty air conditioning in a vehicle, traffic delays and temperatures that swing widely from morning to afternoon can cause temperature excursions. And, sometimes, packaging simply fails.

The ideal shipping temperature depends on the type of sample and the test to be run, but requirements tend to be around 4°C for samples requiring refrigeration and 25°C for those stable at ambient temperature. Regardless whether cool or ambient temperatures are required, the samples can be damaged by excessive heat. That, in turn, reduces the accuracy of the tests that are performed on them.

The outcomes of these blood tests have a huge impact on patients’ quality of life so, obviously, accuracy is important. The tests identify and quantify biomarkers in the blood that tell physicians whether kidney disease is stable or advancing and, ultimately, whether dialysis is needed and whether it is working. Timely, accurate data helps physicians manage their patients’ chronic kidney disease more confidently.

When labs know whether the blood samples experienced thermal excursions, lab technicians know whether to run tests using the samples they have or to request another sample.

For patients, this can mean the difference between maintaining one’s quality of life or beginning the personal and professional disruptions associated with dialysis treatments. (Dialysis typically requires three weekly treatments of four hours each, or overnight treatments.)

WarmMark Provides Insights

One leading dialysis center, recognizing the importance of proper and reliable sample handling procedures, decided to monitor the temperature of blood samples while they were transported. This simple step not only helps improve patients’ quality of life and safety, but also improves the efficiency and accuracy of the laboratory (thereby improving its reputation) and reduces costs for the laboratory and medical insurers.

This large dialysis center, with operations worldwide, chose SpotSee’s WarmMark temperature indicator labels and stickers. This single-use color-change indicator shows lab technicians, at a glance, whether the blood samples experienced brief, moderate or prolonged temperature excursions. With that information, they know whether to process and test the sample or contact the physician for another.

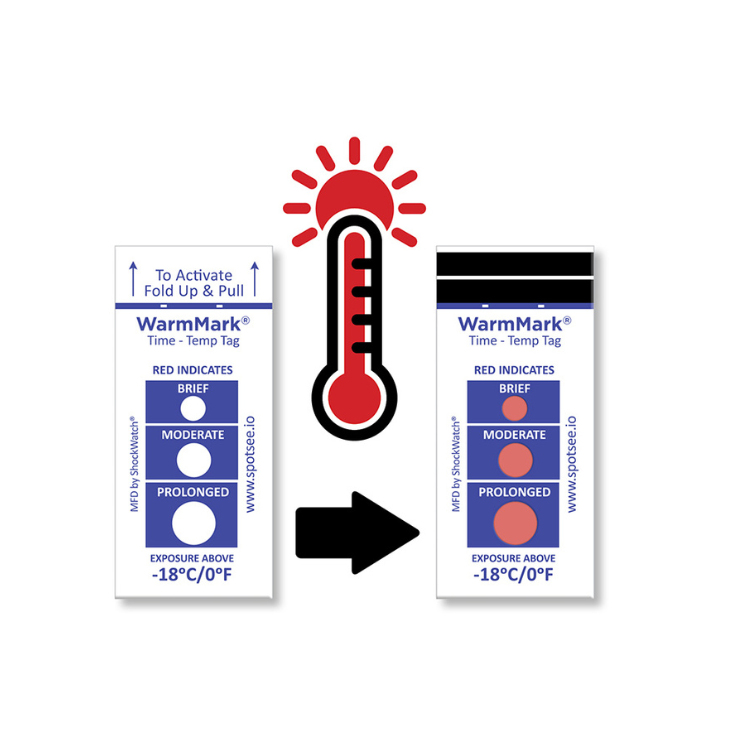

WarmMark is available in a range of critical temperature thresholds, starting at -18°C and ending at 37°C. Indicators for the 8°C and 25° C thresholds that are so important in the healthcare industry are included in that range. Each WarmMark heat indicator features three color-change dots, each of which is associated with the threshold temperature and the duration of any temperature excursion. When a threshold is breached, the indicator dot changes from clear to red. If the excursion continues for a specified time period, the second dot changes to red. For long durations, the third dot changes color. That way, lab technicians can make informed decisions about how to proceed.

WarmMark thermal indicators are as easy to use as they are to read. The dialysis center simply adds the WarmMark temperature card to the box containing the blood samples and ships it as usual. When the package arrives, lab technicians have visual confirmation showing whether the samples exceeded safe thermal thresholds and, if so, for how long. Then they know what steps to take to protect the integrity of the results.

SpotSee is dedicated to protecting shipments of all sorts from environmental events that impair their integrity. To learn more about how WarmMark and other solutions can protect your shipments, contact SpotSee.

Related Case Studies