Hot Water Tank Case Study

Sector: ENGINEERING

Project

One of the leading, independent manufacturers of stainless steel hot water tanks and pressure vessels in Europe produce more than 120,000 hot water tanks, with a capacity of 1 up to 1000 liters. With their excellence in hot water tank engineering, the temperature aspect is very important, however, if the temperature has been set too high the tank can corrode.

Aim

To provide a system to check whether the water temperature of the tank has reached excessive temperatures.

Solution

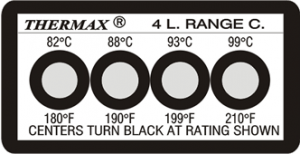

Each tank is fitted with an Irreversible Thermax® 4 Level Range C, therefore if the boiler is returned (for any reason), the manufacturer can easily check that the temperature was not set too high. The indicator forms part of their Quality Control measures and warranty procedures.