This company implemented a ShockWatch RFID impact indicator program to reduce supply chain damage. See how it works.

Summary: They needed a cost-effective solution that could track individual product damage and alert supply chain managers of the damage before the product moves further along in the supply chain.

Product Solution: ShockWatch RFID

Read The Story

Laboratory Equipment Manufacturing: ShockWatch RFID

Industry: Laboratory Equipment Manufacturing

Application: Laboratory equipment manufacturers make a variety of products like freezers, ovens, incubators, fume hoods, pumps, mills, grinders, and ultrasonic cleaning tanks.

Challenge: A major laboratory equipment manufacturer was experiencing a high rate of internal supply chain damage to unsold product that was being transferred from their manufacturing plant to their distribution warehouse. The company needed a cost-effective solution that could track individual product damage and alert supply chain managers of the damage before the product moves further along in the supply chain.

Solution: The laboratory equipment manufacturer chose to implement a ShockWatch RFID impact indicator program. Their process is shown below:

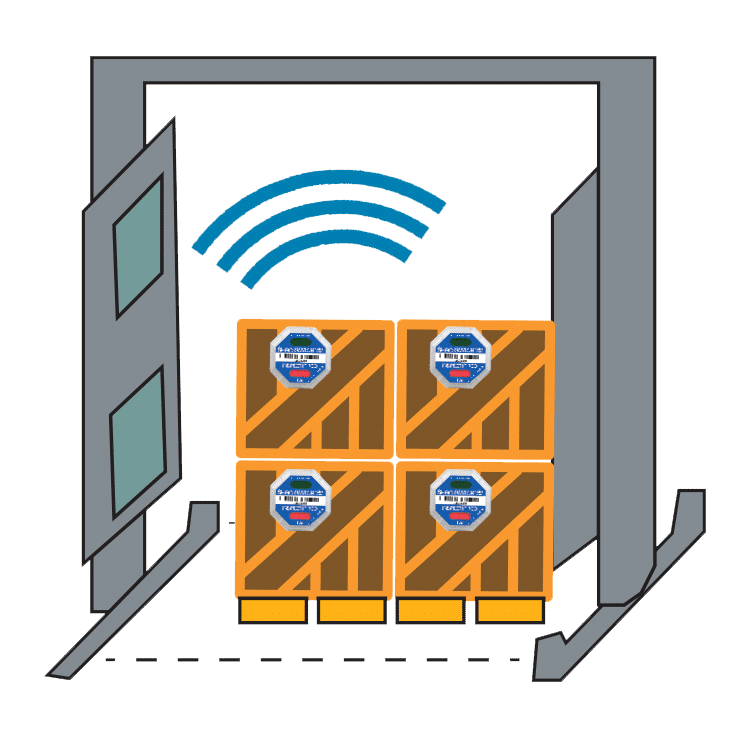

- The manufacturing company already had standard UHF RFID readers positioned at each dock door. To complete their setup, all they needed to do was configure their readers to read the “impact event” that could be signaled from an activated ShockWatch RFID unit. (ShockWatch RFID can replace existing UHF RFID tags used for inventory control)

ShockWatch RFID is affixed to the packaging of all sensitive or fragile laboratory equipment in the company’s supply chain, before it leaves the manufacturing facility

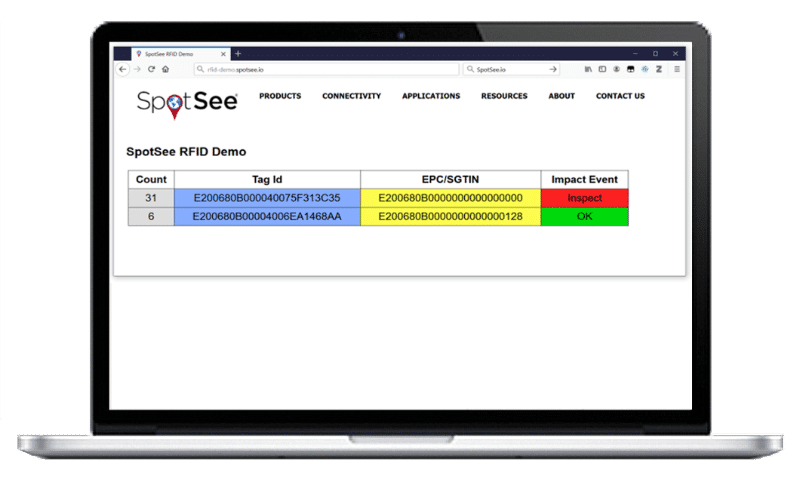

As the damaged product is loaded on to the truck and passes by the RFID readers at the dock doors, the “impact event” associated with the specific product is automatically entered into the company’s warehouse management system.

As the damaged product is loaded on to the truck and passes by the RFID readers at the dock doors, the “impact event” associated with the specific product is automatically entered into the company’s warehouse management system.

Any potentially damaged product is pulled for inspection by quality assurance.

Summary: On top of quickly identifying damaged goods without a visual inspection, the company noticed a shift in behavior from supply chain workers, because ShockWatch RFID acted as a visual deterrent for unacceptable handling and assigned accountability for supply chain damage.

Every company wants to improve their supply chain processes. RFID technology aided companies in improving inventory control. The ShockWatch RFID impact indicator allows companies to leverage the inventory tracking benefits of RFID and the benefits of an impact monitoring program. With ShockWatch RFID impact indicators, the need for visual inspections during the receiving process is greatly reduced. When shipments are scanned, the receiver will know if there has been a potentially damaging impact. If the ShockWatch RFID has activated, inventory can be isolated for further inspection. If there has been no impact, the shipment can be moved into saleable inventory.

ShockWatch RFID impact indicators deliver all the benefits of an impact monitoring program – reduce damage from mishandling, refine supply chain processes so mishandling can be prevented, drive down costs – plus an electronic record of the information. Armed with data, it is possible to track down trouble spots in the supply chain and implement process changes to improve outcomes.

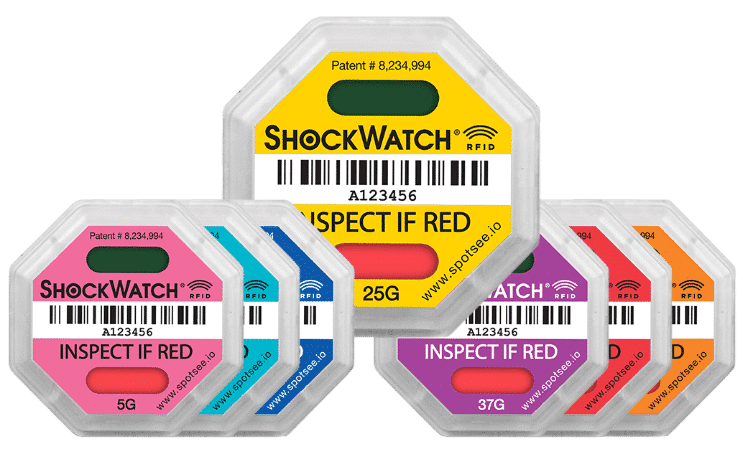

ShockWatch RFID impact indicators are single use devices that are tamperproof, field armable, turn red when an impact occurs and can be scanned with a standard UHF reader. Passive RFID technology is employed in the indicator so there is never a battery life issue to consider.

Benefits:

- Acts as a visual deterrent to mishandling

- Expands the utility of RFID with damage monitoring

- Reduces receiving times and isolates items that need inspection

- Reduces mishandling through awareness

- Helps identify trouble spots in the supply chain from production to transportation to storage

Contact us with any questions you have about this case study or to schedule a meeting with a SpotSee operations expert!