Q&A: What Makes Liquid Crystal Thermometers a Smart Choice for Temperature Monitoring?

As industries from healthcare to manufacturing face increasing pressure to ensure temperature compliance across the supply chain, liquid crystal thermometers offer a simple and effective solution. These non-powered, visual tools have become essential for companies needing real-time feedback without the cost or complexity of electronic sensors. In this article, we answer some common questions about liquid crystal thermometers and connect them to SpotSee’s expanding portfolio—especially following its acquisition of Hallcrest, a pioneer in thermochromic technology.

Q: What is a liquid crystal thermometer?

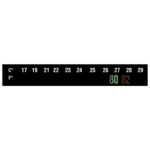

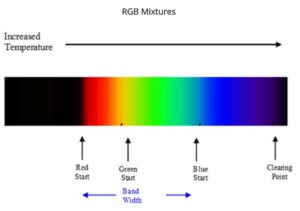

A liquid crystal thermometer is a passive device that uses temperature-sensitive liquid crystals to visually indicate temperature changes. When exposed to specific temperatures, these crystals reflect different wavelengths of light, displaying a color that corresponds to a temperature range.

Q: How do liquid crystal thermometers work?

Liquid crystals are designed to twist or align differently at certain temperatures. As they shift, the color they reflect changes—typically along a gradient from blue to green to red. This makes it easy for users to instantly see if an item is within the desired temperature range.

Q: What are the main advantages of using liquid crystal thermometers?

- Visual immediacy: They provide an instant, easy-to-read color change based on temperature.

- No power required: These indicators function without batteries, making them ideal for remote or in-transit use.

- Safe and non-toxic: Unlike mercury thermometers, liquid crystal products are more environmentally friendly and safe to handle.

- Reversible temperature tracking: Many models reset once temperatures return to normal, making them useful for reusable or continuous monitoring.

- Customizable temperature ranges: Liquid crystal indicators can be tailored to specific temperature thresholds depending on the application.

- Cost-effective: Their affordability makes them ideal for high-volume deployment in shipping, packaging, and diagnostics.

Q: Where are liquid crystal thermometers commonly used?

Liquid crystal indicators are used across a wide range of industries, including:

- Pharmaceuticals: To ensure vaccines, biologics, and other temperature-sensitive medications remain in range during storage and transit.

- Healthcare: As skin or forehead thermometers for quick diagnostic readings.

- Food logistics: For verifying compliance during cold chain transportation.

- Manufacturing and electronics: For detecting temperature fluctuations on surfaces or components.

Q: Are these indicators reversible or irreversible?

Most liquid crystal thermometers are reversible, meaning they return to their original color once the temperature normalizes. This makes them ideal for reusable or continuous monitoring.

In contrast, irreversible indicators permanently change once a specific temperature threshold is crossed. SpotSee offers a range of irreversible indicators, including the Thermax line—widely used in industrial applications to confirm that a product or surface has exceeded a critical temperature.

Q: How does SpotSee fit into this liquid crystal product space?

SpotSee, a global leader in condition monitoring, expanded its temperature monitoring capabilities through the acquisition of Hallcrest, a company with deep expertise in liquid crystal technology. This integration enables SpotSee to offer both reversible liquid crystal thermometers and irreversible indicators such as:

- Reversible

- Liquid crystal indicators: Reversible labels for medical, industrial, and packaging use cases.

- Irreversible

- Thermax: Irreversible temperature labels that provide a permanent record of thermal exposure.

- WarmMark, ColdMark, FreezeSafe, ColdChain Complete and ColdSnap: Irreversible time-temperature indicators that show if products have been exposed to out-of-range temperatures during shipping.

Together, these tools support SpotSee’s mission to provide visual and connected indicators that protect product quality across the supply chain.

Q: Are liquid crystal thermometers better than electronic data loggers?

Not necessarily better—just different. Liquid crystal thermometers are ideal for instant visual feedback, especially in situations where cost or simplicity matters. However, if you need continuous data recording, alarms, or digital reporting, an electronic temperature data logger like SpotSee’s SpotBot GL- a 4G connected location, shock, temperature and humidity device – or MaxiLog Alert, may be a better fit.

Many companies use both: liquid crystal indicators for front-line, low-cost visibility and electronic loggers for audit trails and regulatory compliance.

Final Thoughts

Liquid crystal thermometers strike a balance between simplicity, effectiveness, and affordability. When used as part of a larger condition monitoring program—like those offered by SpotSee—they provide actionable insight that helps protect quality, ensure compliance, and reduce waste.

Want to learn more about liquid crystal technology or irreversible temperature indicators like Thermax? Visit SpotSee.io to explore the full temperature monitoring portfolio.