Cabinetry Case Study: SpotBot Cellular

Summary: SenseIT IoT by Domain, combined with SpotBot Cellular, determines the impact level where damage may occur.

Product Solution: SpotBot Cellular

Read The Story

Cabinetry Case Study: SpotBot Cellular

Company Profile

Industry: Drug Testing Facilities

Application: Condition monitoring the

shipment of fine cabinetry

Challenge: Determine the impact level where damage may occur

SenseIT IoT Provides Insight into Shipment of Fine Furniture

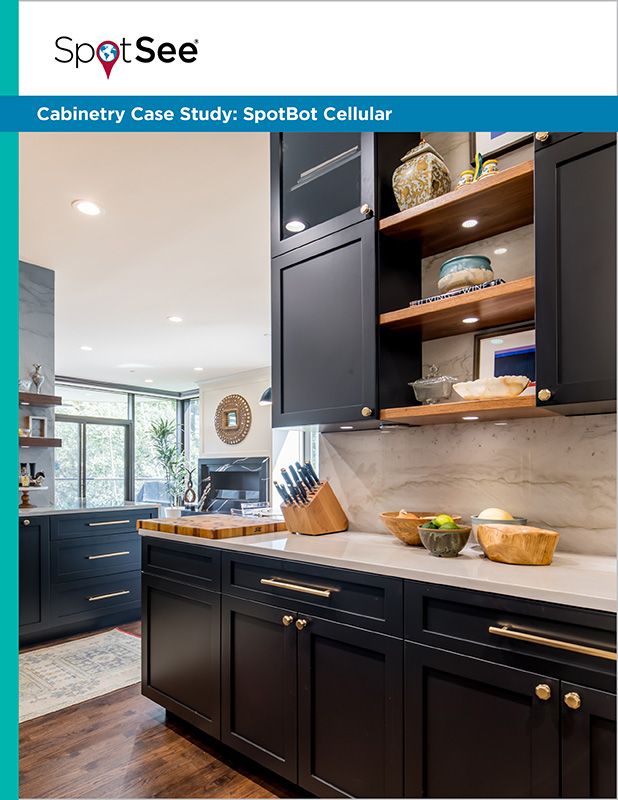

When fine furniture and cabinetry leave the manufacturer, it is perfect. Doors are properly aligned. Drawers open and close smoothly. Finishes are flawless. After traversing hundreds or thousands of miles, sometimes that is no longer the case.

“A fine cabinetry maker in Lancaster County, Pennsylvania, set out to learn why. It knew, of course, that high temperatures could damage finishes, high humidity can swell the wood, and that impacts could break glass panels and cause doors and drawers to become misaligned. What it didn’t know was the exact thresholds where such damage occurred. Therefore, it added SenseIT IoT by Domain, combined with SpotBot® Cellular to its shipments.

“A fine cabinetry maker in Lancaster County, Pennsylvania, set out to learn why. It knew, of course, that high temperatures could damage finishes, high humidity can swell the wood, and that impacts could break glass panels and cause doors and drawers to become misaligned. What it didn’t know was the exact thresholds where such damage occurred. Therefore, it added SenseIT IoT by Domain, combined with SpotBot® Cellular to its shipments.

A quick check of the log shows that between the manufacturing site in Lancaster County, Pennsylvania, and its destination in Dallas, Texas, the cabinetry experienced three exceptions. Detailed information showed where and when they occurred. One impact was to its relatively low 20G impact threshold. By setting the impact threshold low, the manufacturer was monitoring to detect the point at which actual damage occurs and use that insight to design more effective crating and packaging. Other parameters may include temperature, humidity, and tilt.

By using this reusable sensor, the company gained real time alerts any time a threshold was exceeded, and a detailed report of exceptions when the shipment reached its destination. With this data, the manufacturer plans to improve its packaging to reduce damage to cabinetry designed for America’s finest homes and organizations. Once the shipment reached its destination, the monitor was returned to the furniture manufacturer for use on subsequent shipments.

SenseIT IoT is a comprehensive condition monitoring system that processes shipment experience data. Specifically, it accepts data from a variety of remote sensors and is designed to accept new types of sensors as they are developed and issue alerts accordingly.

One of the key advantages of SenseIT IoT is the integration capabilities that are incorporated into SenseIT IoT. Consequently, this monitoring solution melds neatly with enterprise resource planning systems such as SAP Business One (and by early 2022, with Sales Force). Consequently, threshold excursions are noted automatically on SAP’s powerful column-oriented, in-memory HANA database.

Integration with this database supports advanced data analysis for current shipments and historically, so shippers can identify trends and learn whether any changes to packaging, routes, or shipping modalities reduced damage in the real-world shipping environment.

Although SenseIT IoT tracks complex data, it is extremely user-friendly and easy to provision. Setting it up takes about 15 minutes. It is just a matter of adding the sensor to the shipment, and then opening the software and defining the shipment: what it is (in this case, fine cabinetry) whether it is hazardous or perishable, its point of origin, its destination, the planned and actual shipping dates, and the thresholds for each type of sensor that is tracking the cargo.

The monitors log data continually and send alerts when any thresholds are exceeded anywhere there is cellular service. That includes all but the most remote areas of the world. Therefore, carriers can address damage when it happens, before it escalates.

In addition to issuing real-time alerts, SenseIT IoT can produce a certificate of product handling (CoPH) when the shipment reaches its destination. The CoPH shows either that no threshold impacts, or excursions were sensed, or, when they did occur, details when and where each event transpired. This document can be used to justify claims with carriers, even when the damage affects only fine tolerances, such as drawer slides and hinge alignment.