Using OpsWatch, This Mining Facility Predicted Sand Silo Failure 19 Days Before It Occurred And Avoided Downtime.

Summary: OpsWatch impact and vibration monitoring system was deployed at a frac sand transload facility in Texas for approximately 6 months. The information from the OpsWatch predicted a number of events that allowed the operation to avoid system failure.

Product Solution: OpsWatch

Read The Story

OpsWatch: Sand Silo

SpotSee’s OpsWatch impact and vibration monitoring device was deployed at a frac sand transload facility in Texas for approximately 6 months. The information from the OpsWatch predicted a number of events that the predecessors to system failure.

At a frac sand facility, sand moves from rail cars up a conveyor system into a storage silo. Keeping the facility running is a top priority. The OpsWatch is a device that monitors low level impact and vibration of equipment while in operation. It records these values and reports changes in the impact / vibration signature in real time. These changes can be used as early warning signs that part of the system being monitored is beginning to experience unexpected stresses and these stresses can eventually trigger system failure. Unplanned downtime in any operation results in additional operating costs ranging anywhere from overtime wages, costs of express shipping new parts to losing customers because of unmet delivery schedules.

To begin the experiment, transload facility set up the OpsWatch device to monitor a sand conveyor and determine the normal operating characteristics of the conveyor system. During that time, the system was monitored by both the facility personnel and the SpotSee support team.

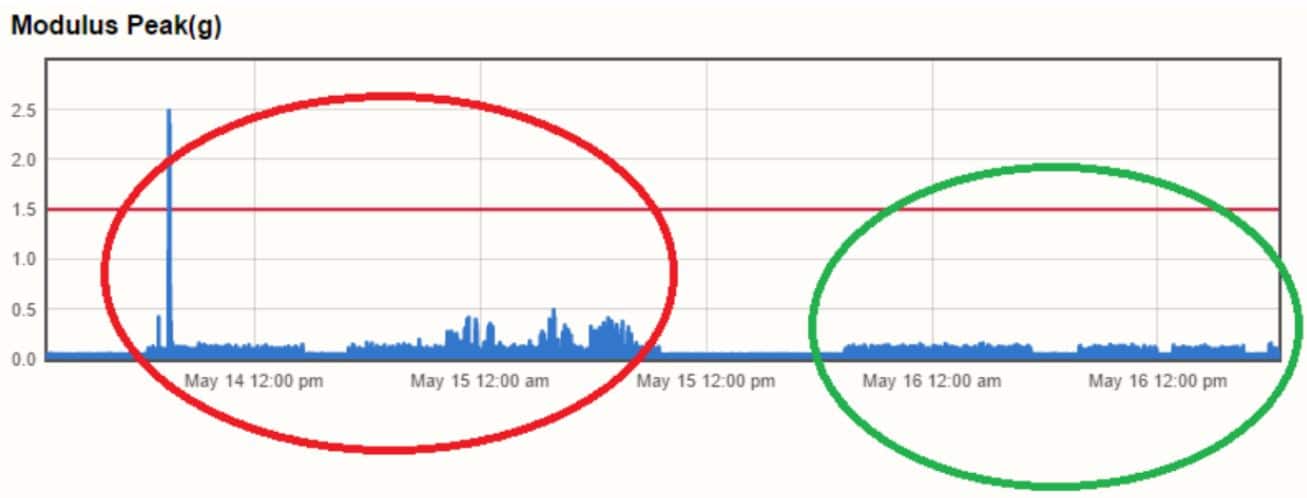

In May, the OpsWatch system was monitoring one of the sand silo elevators at the facility. An unexpected impact spike was recorded. In the hours following the spike, the OpsWatch began recording “chatter.” Something was causing frequent low impacts that were not part of the normal signature of the equipment. The maintenance team stopped the elevator and investigated the issue. It was discovered that the elevator required service. After the service was performed and the elevator was restarted, the chatter was no longer recorded and the facility avoided equipment degradation and potential failure.

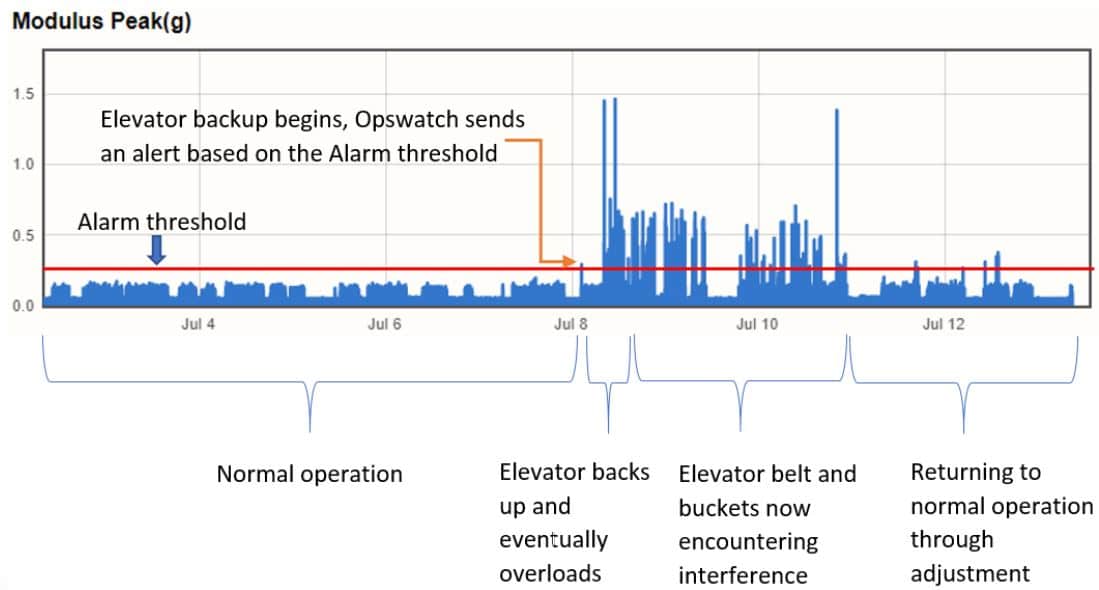

In the example below, on July 8th, the elevator system in the silo started to back up and a spike was recorded. Over the next day several days, the elevator belt and buckets were out of alignment and the system was not operating at peak performance. The facility operations team was able to make an adjustment and the system was returned to normal operation.

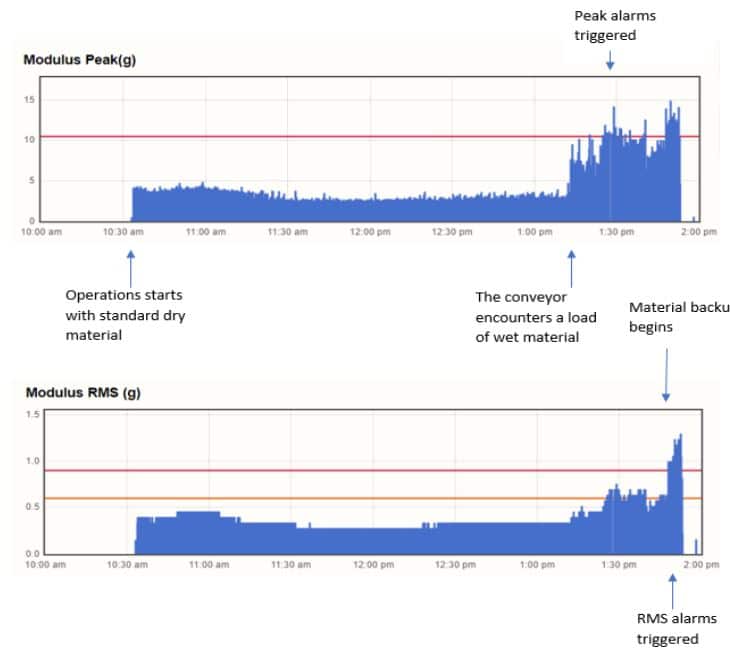

Elevators / conveyors out of adjustment are not the only hazards encountered in a frac sand facility. In one instance, a railcar loaded with sand had water leak into the load. Instead of standard, dry sand, the conveyor was moving wet sand. The weight of the sand was significantly increased. When the wet sand landed on the conveyor, the system had to work much harder to move the sand. As the weight continued to build on the conveyor, so did the vibration. Because the sand did not flow into the silo as expected, the material began to back up on the conveyor which further stresses the conveyor system. The operator reacted to the alarms and shut down the conveyor.

Elevators / conveyors out of adjustment are not the only hazards encountered in a frac sand facility. In one instance, a railcar loaded with sand had water leak into the load. Instead of standard, dry sand, the conveyor was moving wet sand. The weight of the sand was significantly increased. When the wet sand landed on the conveyor, the system had to work much harder to move the sand. As the weight continued to build on the conveyor, so did the vibration. Because the sand did not flow into the silo as expected, the material began to back up on the conveyor which further stresses the conveyor system. The operator reacted to the alarms and shut down the conveyor.

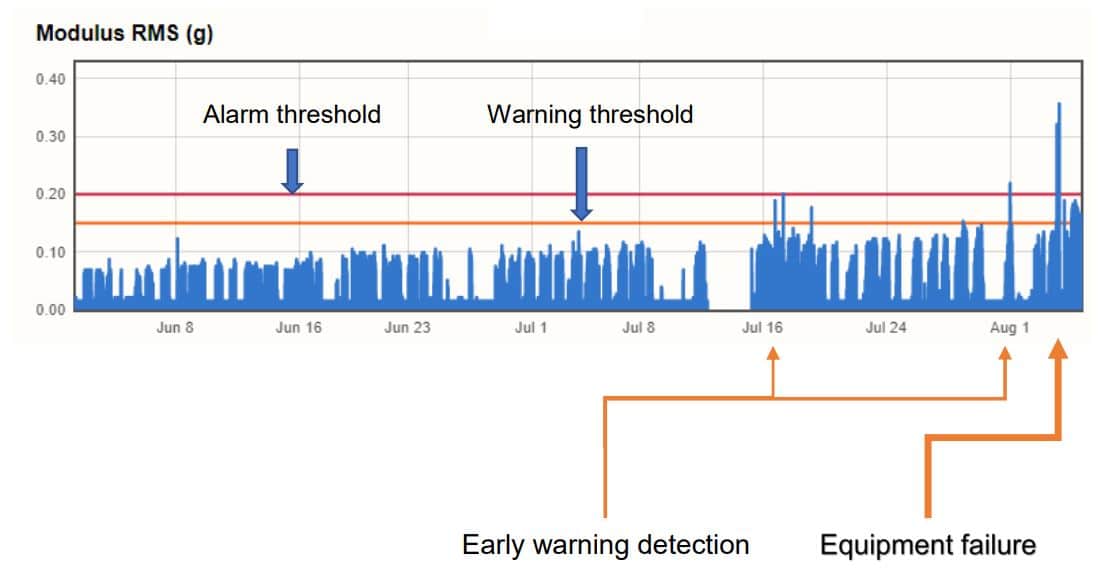

However, the warnings of the OpsWatch were not always heeded and the consequences to the facility were significant. In one instance, the OpsWatch system recorded increasing vibration values beginning 19 days before an incident, but the alarms were not addressed by the operations team. This particular case resulted in equipment failure and downtime for the facility.

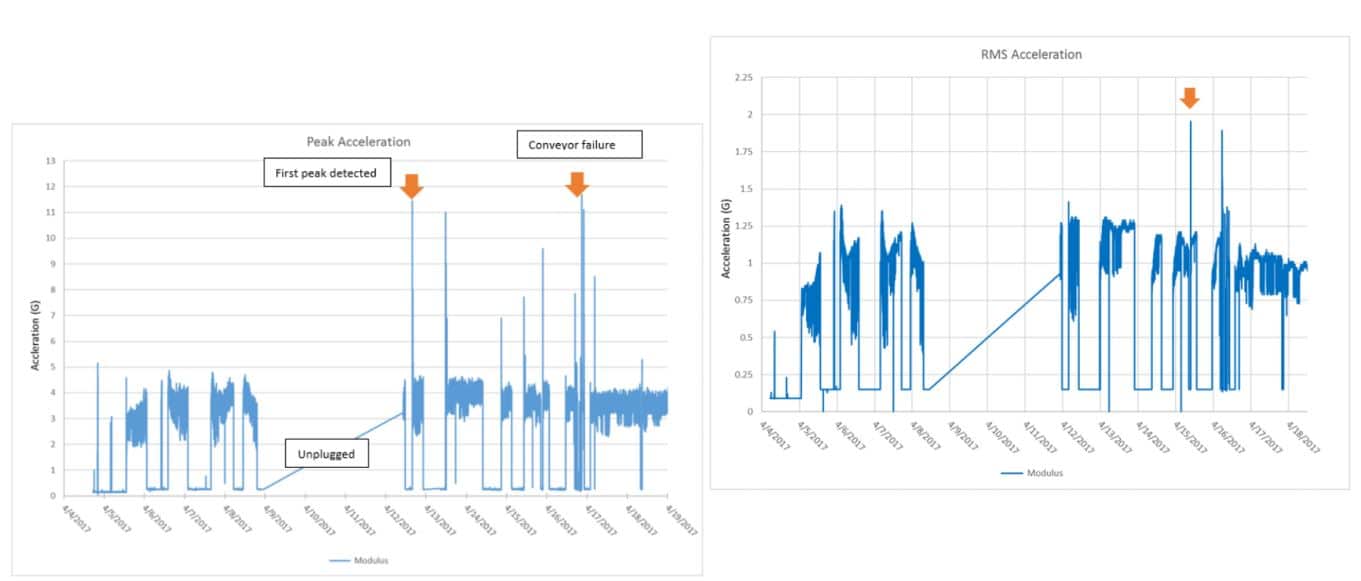

In another case, escalating impact and vibration peaks were detected by the OpsWatch. The conveyor was not inspected and allowed to continue running. Unfortunately, not only did the facility have to deal with a conveyor failure but 210 tons of frac sand were dumped into an equipment area. The removal of the sand required specialized equipment and cost the company over $20,000 in clean up costs along.

Unexpected impacts and unacceptable vibrations can result in significant costs to your operation. SpotSee experts are available to assist you in developing a monitoring system that allows you to know what is happening before failure occurs. For information on an OpsWatch shock and vibration monitoring program, fill out a contact form or email us at info@spotsee.io.

Contact us with any questions you have about this case study or to schedule a meeting with a SpotSee operations expert!