Wax Melt Temperature Indicator Label Technology

Wax Melt technology dates back to the 1940s, when it was originally developed during the second World War to show when food rations had been exposed to excessive temperatures. Today, the small number of original temperatures has been greatly expanded upon.

The most common use of Wax Melts is its self-adhesive thermometer labels, used in a huge number of common applications including:

- Warranty Indicators

- Electrical Overheat Indicators

- Process Thermometers

- Brake Caliper Thermometers

- Monitoring Shipping Temperatures

- Textile Fusing Thermometers

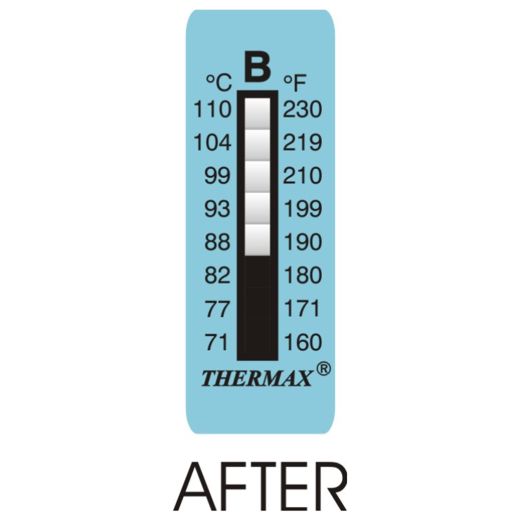

Each element changes color distinctly as its rated temperature is exceeded. The changes are irreversible, providing a temperature history of the surface being monitored. The labels will not de-laminate when removed for reference and can be attached to an inspection report to serve as a permanent record of attained temperature.

HOW THE LABELS WORK:

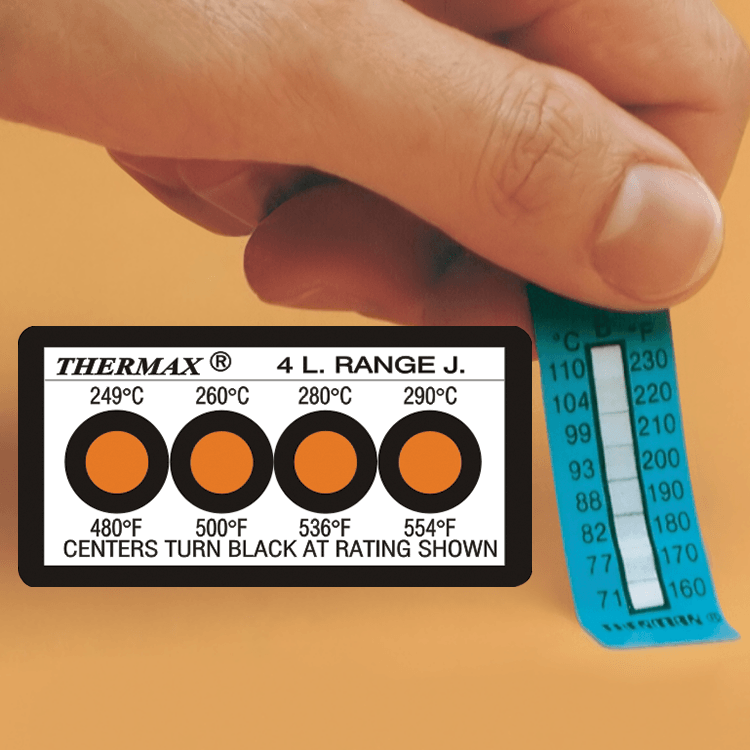

The temperature-sensitive elements are phase-change indicators which use the sharply defined melting points of a series of specially purified organic chemicals to give the unique, high precision, color change effects. Each temperature element uses a different chemical compound and is made separately by applying a coating containing the chemical to a special absorptive paper substrate, which is usually black. When the rated temperature is exceeded, the chemical melts and is absorbed by the substrate, causing a permanent color change to black. Up to ten elements can be combined on a single label.

The waxes melt over a relatively sharp range of temperature and can be formulated to react to many temperatures between -29°C (84°F) and 290°C (554°F) and react to changes in temperature as small as 0.2°C (0.4°F). Accurate to up to +/- 1°C to 100°C, +/-1.5°C to 154°C and +/-4°C across the rest of the range, if stored and used correctly.

RECORDING DISHWASHER SURFACE TEMPERATURE

Thermostrip DL labels confirm that sanitizing temperatures were reached during a dish washing cycle. These labels provide an easy method of record-keeping.

Shelf Life:

- Temperatures up to 36ºC (96.8ºF) 6 months from date of invoice when stored in a refrigerator.

- Temperatures up to 49ºC (120ºF) 12 months from invoice date when stored in a refrigerator.

- Temperatures 50ºC (122ºF) to 290ºC (554ºF) 24 months from invoice date when stored in cool dark environment between 18 and 22ºC.