The Easy Path to Automotive Supply Chain Monitoring With SpotSee

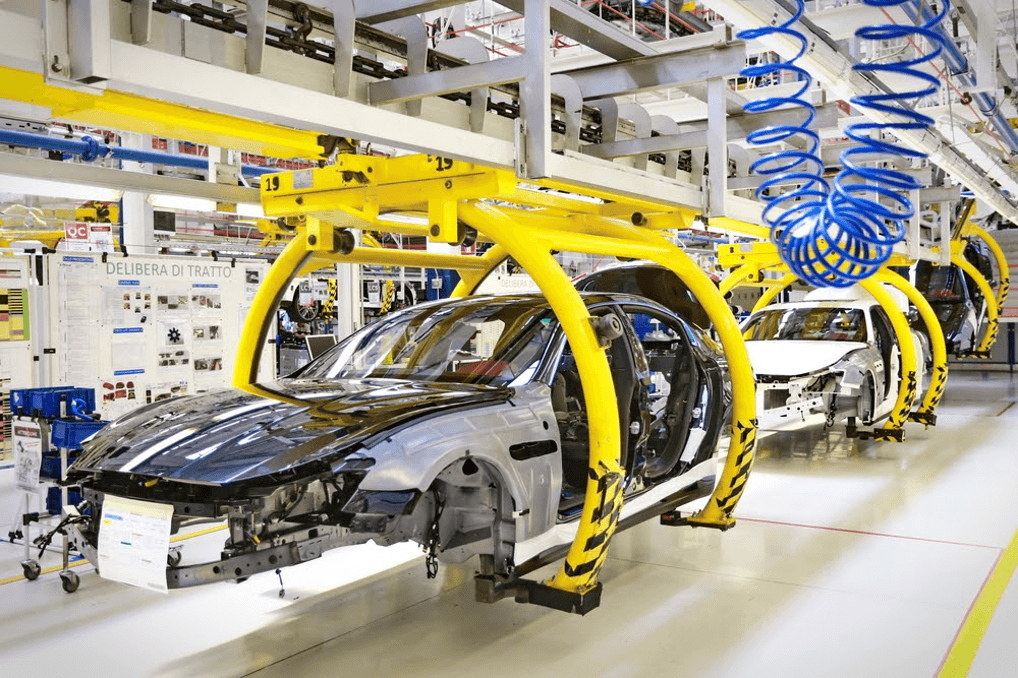

Managing an automotive supply chain is one of the most challenging logistics careers. An average vehicle contains over 30,000 parts and delays in just one part of the supply chain can slow down and even halt production.

Automotive manufacturing is further complicated by the fact that many key components are fragile and sometimes get damaged during transit or handling. Not knowing where the damage is occurring or what is causing it makes the problem difficult to correct.

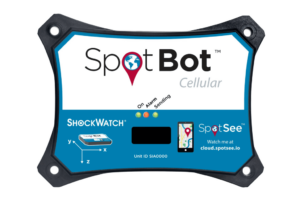

Fortunately, solutions are available that allow automotive supply chain managers to monitor the process and detect exactly when and where problems are occurring. SpotBot Cellular(R) by SpotSee enables businesses to monitor impact and temperature conditions in real time from anywhere around the world.

Let’s take a closer look at how monitoring the supply chain empowers automotive businesses to prevent costly damages and streamline their operations.

SpotBot Cellular: Impact Recorder for Automotive Supply Chain Management

SpotBot Cellular is an affordable device that allows you to monitor your supply chain in real time for sudden impact and temperature changes that can damage sensitive automotive parts. Here are some features that make it the ideal choice for automotive supply chain monitoring.

SpotBot Cellular is an affordable device that allows you to monitor your supply chain in real time for sudden impact and temperature changes that can damage sensitive automotive parts. Here are some features that make it the ideal choice for automotive supply chain monitoring.

- Real-time impact and temperature notifications – Discover issues in real-time so that you can take immediate action to prevent damage during transport.

- Best impact detection data – Impact is the leading cause of automotive damage in the supply chain. SpotBot Cellular allows you to detect when impact levels exceed your selected thresholds.

- Longest battery life – SpotBot Cellular has the longest battery life in the industry, making it a great choice for global and long-term supply chain monitoring.

- Low Cost – SpotBot Cellular can send data to anywhere in the world where there is a cellular signal. SpotSee owns its own mobile network allowing for low-cost global communication with no roaming fees or surprise charges.

SpotBot Cellular Supply Chain Monitoring Reduces Damage for Automotive Manufacturers

A major automotive company experienced a high rate of damage in their supply chain. They ship over 30 million car parts in 7,000 containers so they wanted to discover and correct the source of the problem.

When you’re making thousands of expensive luxury vehicles every day, a well-oiled supply chain is imperative. Without expansive stocks of inventory on hand, parts must be shipped in daily from local and regional suppliers precisely in sequence so production goes off without a hitch. When even a minute of downtime can cost thousands of dollars, receiving damaged parts is a major concern.

Component racks that held instrument panels passed vibration and impact testing, but the panels still arrived damaged. The company didn’t know what was causing the damage or where it was occurring, so they turned to SpotSee and SpotBot Cellular to find the cause of the problem.

Using SpotBot Cellular’s impact recorder and real-time monitoring, the company discovered why the panels were falling off the racks. Using this knowledge, they were able to educate material handlers and improve automotive supply chain management methods that they used to ship the instrument panels to prevent future damage.

By attaching a SpotBot Cellular impact recorder to proprietary racks that traveled on a loop between the plant and its suppliers, the automotive manufacturer collected mounds of data via cellular connectivity that allowed them to get to the root of the problem. Sometimes, it was something as simple as a supplier not lowering safety bars on the racks, which led to components bouncing around on bumpy roads. In other cases, the company found opportunities to better design its own racks or better regulate the use of suppliers’ racks.

What started as a plan to protect instrument panels along their journey then evolved, after optimizing that supply chain, to address handling issues with radiators. Then headlights. And so on. Eventually, the manufacturer decided to design all-new component shipping racks — with SpotBot Cellular built in.

The impact recorder data from SpotBot Cellular enabled logistics managers to zero in on problems — Was it a transport issue or a packaging issue? Where did it happen? When did it occur? — and find out the most vulnerable parts of its supply chain, which included multiple cross-dock handoffs.

SpotBot Cellular’s data empowered the major auto manufacturer to face its choices: do nothing and maintain the status quo, accepting an imperfect supply chain — or recoup money lost to damage by making smart, data-backed choices in supply chain improvements. Along the way, the manufacturer and SpotSee worked together to refine data analysis and cloud setup. SpotSee also introduced passive, go/no-go indicators for ongoing detection once a monitor was able to identify a blanket issue.

Part of what made the process so valuable was its simplicity and ease of operation. That isn’t just a reflection of the real-time instant notifications of damage that gave new transparency to the supply chain. It came down to the easy setup and implementation of SpotBot Cellular, with SpotSee product experts on the ground at the plant itself to walk the automotive team through implementation . Ongoing support gave the automotive team the confidence and ability they needed to gain valuable insights from SpotBot Cellular as they expanded its use and continually discovered opportunities for optimization.

SpotSee Works with You to Improve Automotive Supply Chain Management

SpotSee’s attentive expert support, as described in the previous section, is not a rarity but rather an inherent part of any SpotSee partnership. We make sure your business can deploy SpotBot — and any SpotSee product — in a way that maximizes value and impact for your unique situation. That’s possible thanks to a consultation, implementation, and operational support team that’s accessible when you need them and eager to help your business time and money.

What’s more, SpotSee’s logistics experts have a trained perspective that identifies additional opportunities for monitoring to keep you running smoothly and maximize the return on your investment. With SpotBot Cellular, businesses are not only connected to data-rich logistical insights, but the devoted SpotSee support team as well.

SpotBot Cellular is the most affordable solution you will find to help you manage and monitor your automotive supply chain. For just a few hundred dollars, this technology could save your organization thousands of dollars each month by helping your detect where and when damage is occurring in your supply chain — and you get a vested partner along the way to implement, investigate, fine-tune, and optimize your logistics.

SpotSee also offers flexible plans to meet customer needs, including 60 day project-based usage of SpotBot Cellular units, or long term licencing of the units for as little as $12/month over the contract period.

Does new technology seem overwhelming to you? SpotSee designed SpotBot Cellular for ease of use so that anyone can use it. SpotBot Cellular is easy to use and set up… no advanced technical skills are required. The SpotSee support team is easily accessible by phone or email if you have any questions.

Most importantly, SpotBot Cellular will allow you to detect where problems are occurring in the supply chain in real-time. Your company can use this data to improve handling processes to prevent future problems or correct issues during transit to prevent damage to expensive parts.

How Can SpotBot Cellular Can Help Your Business?

Detecting issues during transit can be especially important for automotive businesses that are using just-in-time inventory management. Improving the reliability of your supply chain and ensuring that components arrive in good condition will give you the competitive advantage your business needs to thrive.

Want to streamline your automotive production, reduce damage, and improve the reliability of your supply chain? Then fill out the contact form below to find out more about SpotBot Cellular, schedule a demonstration, and learn how we can help your automotive operation.