Who to Hold Accountable in Your Supply Chain

To say the global supply chain is complex is an understatement. Just look at the pharmaceutical industry. More than 60,000 suppliers across 80 countries contribute to Roche’s 1,000+ diagnostic tests, tools, and medicines. And, in aerospace, 367,000 parts are sourced from hundreds of suppliers for Boeing’s smallest commercial jet, the 737.

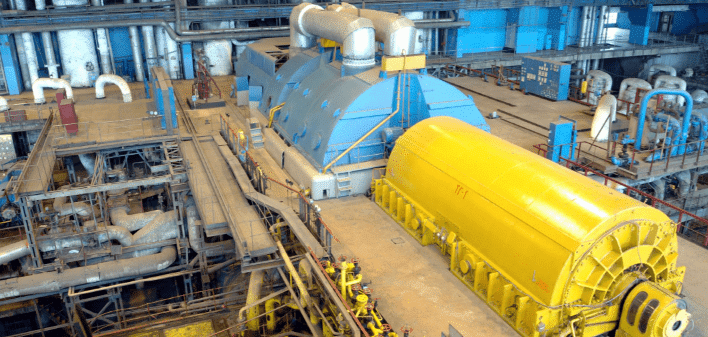

The complexity extends to other industries, too. Even products as seemingly straightforward as wind turbines start with rare earth elements mined (usually) in Australia or China, before being manufactured from components made by multiple suppliers, and then shipped throughout the world. Even king crab harvested in Alaska undergo a few handoffs before they grace your plate at your favorite seafood restaurant.

The complexity extends to other industries, too. Even products as seemingly straightforward as wind turbines start with rare earth elements mined (usually) in Australia or China, before being manufactured from components made by multiple suppliers, and then shipped throughout the world. Even king crab harvested in Alaska undergo a few handoffs before they grace your plate at your favorite seafood restaurant.

That’s why accountability in supply chains is so important. To achieve supply chain improvement — and save time and money via damage reduction — you need to know not just what happened, but under whose watch. That’s why you need supply chain monitoring. Cue SpotSee’s shipping monitors.

Impact, Vibration, and Temperature Affect Quality

For each of these products, handling matters. Incidents involving impacts, vibrations, or temperature excursions can cause damage that either requires repairs or makes the product unsafe — or even deadly. While these events may occur at any time, products are at greatest risk during handoffs – when they are being loaded onto ships, trains, or trucks – and, for temperature sensitive chemicals and pharmaceuticals, while they are sitting on tarmacs.

A fully optimized supply chain monitoring program makes it clear not only that damage occurred, but also when, where, and at what level of severity that damage occurred so you can discover any weak points in your supply chain and take steps towards damage reduction. For example, knowing that an impact occurred at the freight yard or temperatures rose just before loading lets you work with your logistics partners to prevent future damage and mitigate existing damage by improving supply chain management.

A fully optimized supply chain monitoring program makes it clear not only that damage occurred, but also when, where, and at what level of severity that damage occurred so you can discover any weak points in your supply chain and take steps towards damage reduction. For example, knowing that an impact occurred at the freight yard or temperatures rose just before loading lets you work with your logistics partners to prevent future damage and mitigate existing damage by improving supply chain management.

Implement a Holistic Damage Prevention Program

Observing damage trends and correlating them to location, carrier, route, lane, or time of year helps you mitigate risks and optimize your entire supply chain.

For example, a steam turbine manufacturer noticed damage to their turbines and specialized rail cars during shipping. With up to $10 million in fragile assets at risk per shipment, the manufacturer wanted to understand the characteristics of an impact and precise locations of impacts that occurred due to drops, shifts,

For example, a steam turbine manufacturer noticed damage to their turbines and specialized rail cars during shipping. With up to $10 million in fragile assets at risk per shipment, the manufacturer wanted to understand the characteristics of an impact and precise locations of impacts that occurred due to drops, shifts,

severe movements, and other unexpected handling conditions. The company added the ShockLog® Satellite impact monitor to shipments to provide that information in real time, thereby clarifying responsibility for damage and minimizing future damage.

In another example, one airlines’ auxiliary power units (APUs) that provided additional power to the ignition were routinely damaged during flight. It installed the SpotBot® Cellular impact monitor and determined the exact time, location, and magnitude of the damage. Further investigation showed the APUs were designed to accept shocks of 9 G, but landing shocks were 13 G, as evidenced by SpotSee’s supply chain monitoring. By learning this, the airline was able to write more robust component specifications and improve its APU mounting solution to prevent subsequent damage.

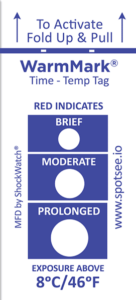

For food, whether it’s shipped around the world or across town, temperatures matter. Foods such as eggs, dairy, and even vegetables and grains need to be kept either below 40°F or above 140°F to slow the growth of dangerous bacteria. Fresh seafood should be maintained between 30°F and 32°F. Temperature is so critical that the FDA advises seafood packagers to add a temperature indicator to the packaging to show whether appropriate temperatures were maintained. The goal is to prevent consumption of seafood tainted with Clostridium botulinum, which grows in warm temperatures.

Many Monitoring Options Are Available

There are many supply chain monitoring options to record impact, vibration, and temperature excursions that can help you hold the right parties accountable for damage events and engage them in supply chain improvement and optimization. SpotBot Cellular, for example, is popular for recording both temperature and tri-axial impact monitoring for products between 100 and 60,000 pounds. SpotBot Cellular’s shipping monitor software annotates impacts, up to 65 G, as well as exceptional temperature changes, on a map to show managers what occurred and where it happened — so they can zero in on the handler accountable.

There are many supply chain monitoring options to record impact, vibration, and temperature excursions that can help you hold the right parties accountable for damage events and engage them in supply chain improvement and optimization. SpotBot Cellular, for example, is popular for recording both temperature and tri-axial impact monitoring for products between 100 and 60,000 pounds. SpotBot Cellular’s shipping monitor software annotates impacts, up to 65 G, as well as exceptional temperature changes, on a map to show managers what occurred and where it happened — so they can zero in on the handler accountable.

If you’re concerned primarily about shock and vibration, and need in-depth, engineer-level metrics on acceleration, duration, and amplitude of a damage event, ShockLog Cellular (also available with USB and satellite connectivity) fits the bill. It’s suited for assets that weigh up to 250 tons, can record 870 events, and features 18 months of recorder battery life plus more than 90 days of connectivity battery life. In situations that require additional parameters to be monitored, add-on modules for temperature, pressure, humidity, tilt, roll, and GPS-monitored location are available.

If you’re concerned primarily about shock and vibration, and need in-depth, engineer-level metrics on acceleration, duration, and amplitude of a damage event, ShockLog Cellular (also available with USB and satellite connectivity) fits the bill. It’s suited for assets that weigh up to 250 tons, can record 870 events, and features 18 months of recorder battery life plus more than 90 days of connectivity battery life. In situations that require additional parameters to be monitored, add-on modules for temperature, pressure, humidity, tilt, roll, and GPS-monitored location are available.

Both SpotBot Cellular and ShockLog Cellular data can be accessed from the SpotSee Cloud for real-time analysis of excursions. It’s available anywhere there’s cellular service — all without roaming fees.

When all you need is go/no go information, ShockWatch RFID®️ is an option. It turns red if products encounter 5 to 75 G of impact, so handlers know which items need inspection and which can enter the production line. The passive RFID chip enables items to be scanned automatically, with a dedicated device or as part of an existing ERP system. The simple, yet effective ShockWatch RFID indicator can reduce damage in the supply chain by 40 to 60 percent, all without wires or batteries.

Benefits of Accountability

Monitors and indicators like these are designed to increase accountability in supply chains. The goal is to identify and fix problems, working with the correct responsible party, so they don’t reoccur. While real-time alerts allow you to take immediate action to remedy today’s problems, monitoring also helps you identify long-term trends that create challenges that may not manifest until after products are installed or in service.

For heavy equipment – turbines, for example – addressing damage early can mean the difference between repairing or replacing heavy equipment in infrastructure-rich areas versus remote field locations, saving both time and money.

For produce, such as oranges or strawberries, it lets you divert shipments to nearby markets and therefore maximize the shelf life of your products and, thus, their sales potential.

For produce, such as oranges or strawberries, it lets you divert shipments to nearby markets and therefore maximize the shelf life of your products and, thus, their sales potential.

There are many examples, but they all have the same results: less damage. That translates to fewer warranty repairs, product replacements, and returned products — and greater customer satisfaction.

Because there are fewer incidents, overall quality is improved. Consequently, as a supply chain manager, you get fewer complaints from internal teams and from customers. Your sales team benefits by not having to placate customers, and your production manager can be more confident and manufacturing more efficient by knowing which items can be slotted into production immediately and which need inspection. And, importantly, your company’s reputation for quality is reinforced — you’ll be known as the company who stands behind their deliveries and gets ahead of damage before it becomes your customer’s problem.

Then, what happens when you’ve mastered your current supply chain? You uncover the confidence to go farther and faster, expanding your business horizons.

Find Out Who to Hold Accountable Throughout Your Supply Chain

Use the form below to get in touch with a logistics expert at SpotSee today to start uncovering – and fixing — the weak spots in your supply chain to reduce damage while saving time and money.