News

What Is an Accelerometer?

Accelerometers are small axis-based devices that can be affixed to items and indicate orientation. In a smart phone, it’s the accelerometer that auto-rotates the screen and tells your stargazing app where it’s pointing in the sky. In a laptop, the accelerometer senses...

Damage in your supply chain? Using RFID to Deter Detect and Diagnose

HOME BLOG POSTS REDUCE WASTE IN YOUR SUPPLY CHAIN Did you know utilizing indicators allows a company greater visibility into their supply chain and reduce damage by up to 40-60%? No one can hide from supply chain damage, but there are solutions that can dramatically...

RFID Shipping Solutions Take Hold at Top Businesses

FedEx says the future of the supply chain includes RFID shipping solutions. CIO Rob Carter made his pronouncement in 2019, touting the RFID tags that feed information — such as temperature, impact, and vibration — into blockchain to create a secure, traceable...

Eye in the Sky: Drones and Passive RFID to Manage Assets

Drones sporting RFID readers are taking flight inside large warehouses, distribution centers, fulfillment centers, big box stores, and air cargo facilities, as well as above freight yards. They started out reading active RFID, but now have embraced passive RFID tags...

The Future of Packaging: RFID Package Tracking Labels

The future of packaging involves RFID tracking stickers. You’ve probably heard that before, but today’s passive RFID tags have won the respect of business leaders who are doing more than just slapping a tag on a crate and calling it done. Passive RFID tags are being...

Impact Recorders for Transformers Empower Accountability, Visibility, and Optimization

The seven tornados that ripped through Chattanooga, TN, on Easter weekend (2020) cost the local electric utility, EPB, an estimated $28 million. EPB has had to replace 709 of its transformers in the hardest hit areas, along 126 miles of replacement wire. That means a...

RFID’s Essential Role in Aerospace Supply Chains

Using RFID tags – Radio Frequency Identification – is helping Boeing and Airbus reduce their parts inventory and speed aircraft repairs. These aerospace giants have each used RFID for years, gradually expanding its use throughout their logistics, maintenance and...

Smart Technologies – Like RFID Labels – Transform Supply Chain in 2020

Digital transformation is one of 2020’s top trends — and challenges — for industrial supply chains, as organizations scramble to become smarter, more automated, and more efficient. When it comes to goods, this means using smart technologies to streamline logistics,...

Free Webinar

RFID Journal featuring ShockWatch RFID by Spotsee

HOME BLOG POSTS REDUCE WASTE IN YOUR SUPPLY CHAIN RFID Journal has launched a series of webinars to highlight the Best New Product finalists of 2020. SpotSee has been chosen as a Best New Product Finalist of 2020 for our ShockWatch RFID. ShockWatch RFID combines the...

SpotSee Supply Chain Monitoring: Save Money, Reduce Damage (Video)

You have a great product that customers need. You’ve designed your supply chain and accounted for everything from manufacturing your items to transporting them to the end customer. But inventory can get damaged during shipping. SpotSee’s logistics monitoring keeps an...

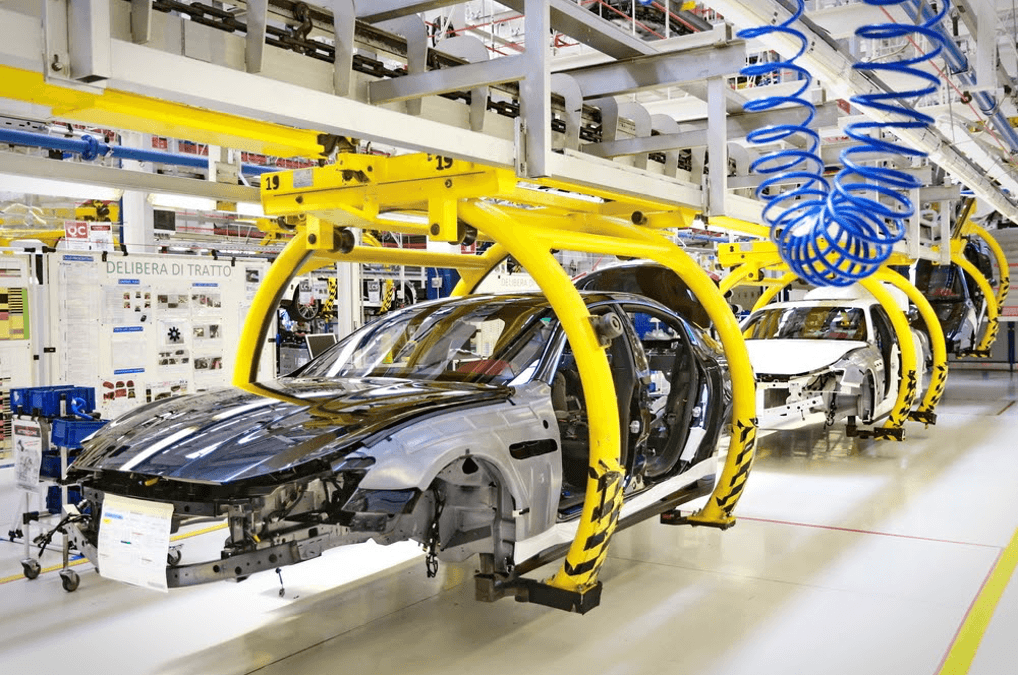

Auto Manufacturers Discover the Advantages of RFID Inventory Management

One of the biggest challenges in automotive manufacturing is precisely managing the thousands of parts that go into creating an automobile. Car manufacturing involves a good amount of complexity as manufacturers produce different models and work with a wide variety of...

Need for Pharma Cold Chain Logistics Monitoring Increases

By 2023, temperature-controlled pharmaceuticals are expected to grow 59 percent from 2017 levels, according to the 2019 Biopharma Cold Chain Sourcebook. Pharmaceutical shippers and carriers, therefore, are finding temperature monitoring devices vital throughout cold...

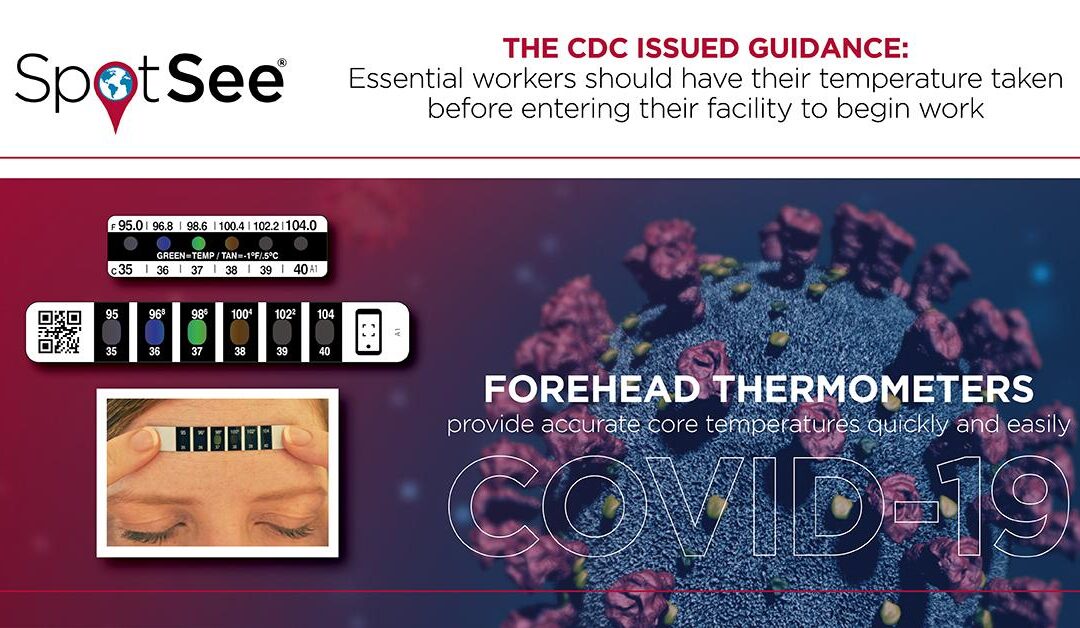

SpotSee Provides Self- Applied Forehead Thermometers to Help Prevent the Spread of COVID-19

As a global leader in supply chain temperature indicators used to monitor test specimens in the SARS and H1N1 virus outbreaks, we provide hands-off forehead thermometers for essential businesses and companies to help ensure workplaces remain fever and virus free...

4 Ways RFID Supply Chains Optimize Automotive Manufacturing

As average per capita income continues to rise, revenue for the automotive industry continues to rise. However, competition continues to grow in the industry and price competition within the industry limits profits for automobile companies. To remain competitive, auto...

The Easy Path to Automotive Supply Chain Monitoring With SpotSee

Managing an automotive supply chain is one of the most challenging logistics careers. An average vehicle contains over 30,000 parts and delays in just one part of the supply chain can slow down and even halt production. Automotive manufacturing is further complicated...

Free Webinar

Damage Control: How to Reduce Waste in Your Supply Chain

HOME BLOG POSTS REDUCE WASTE IN YOUR SUPPLY CHAIN Join Jan van Niekerk, Vice President of Engineering and Innovation at SpotSee and Lou Parker, Vice President of Strategic Development at Smart Label Solutions, as they discuss how to reduce waste in your supply chain....

SpotSee Featured on Supply Chain Now Podcast

Jan Van Niekerk, our VP of Engineering and Innovation joins Scott Luton and Greg White of Supply Chain Now to discuss leveraging technology to protect your shipments during transit. Jan explains the Three D’s to protecting your supply chain; Detect, Diagnose, and...

SpotSee Donates Temperature Indicators to Mexico for COVID-19 Specimens

As a global leader in supply chain temperature indicators used to monitor test specimens in the SARS and H1N1 virus outbreaks, are donating 10,000 temperature indicators to the State of Chihuahua, Mexico, to assist with transporting test specimens of the coronavirus...

Tilt import protège les tests de dépistage du Covid-19

Le fournisseur de matériel de contrôle du transport augmente son offre de cartes indicatrices de température pour faire face à la demande des hôpitaux et des laboratoires. Les indicateurs de température sont connus depuis longtemps. Basés sur l’emploi de technologies...

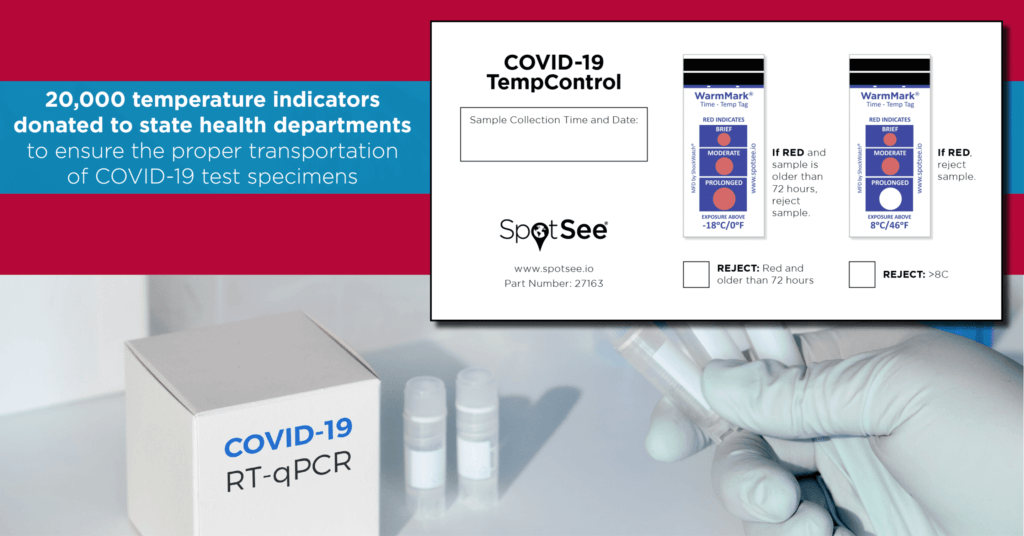

SpotSee Donates Temperature Indicators to US State Health Departments for COVID-19 Specimens

SpotSee a global leader in supply chain temperature indicators used to monitor test specimens in the SARS and H1N1 virus outbreaks, have offered 20,000 temperature indicators to state health departments nationwide to assist with transporting test specimens of the...