4 Ways to Embrace Supply Chain Technology of the Future, Today

Innovative technology continues to improve the way we do business, from our communications and marketing to developing and manufacturing new products. Even the way we transport goods changes continuously due to new technological advancements — but sometimes it seems like the truly futuristic supply chain technology is just too far off to realistically consider.

That doesn’t have to be the case, though. Let’s look at supply chain technology of the future that you can already embrace, implement, and deploy today.

Before a product reaches the consumer, it passes through multiple handlers. Inefficiencies can occur anywhere between the manufacturer and the end-user. Supply chain technology can cut costs, enhance the quality of goods, and hasten deliveries to end-users.

Here are four technologies that forward-thinking businesses are using to streamline their supply chains.

Robotics

Monotonous factory and warehouse operations like picking and packing are labor-intensive and time-consuming. Automation technologies like robotics are fast replacing human handlers in completing repetitive tasks. They are developing rapidly and have piqued the interest of many new players.

Today, renowned manufacturers of material handling machinery like forklifts and cranes deploy automation features on their products. Some mechanized picking systems in factories can manage around 2,400 picks every hour. With advanced machine vision technology, they can detect and handle items presented in random orientations and positions. We’ve also witnessed robot arms and driverless vehicles working reliably alongside humans.

Swift completion of tasks through warehouse automation has enhanced productivity and performance in factories. It has also contributed to high service levels, enabling same-day order fulfillment and product delivery.

Furthermore, automation cuts labor overheads and boosts storage density in warehouses. Its low running cost and high throughput allow companies to recoup the installation cost within a relatively short period.

IOT in Transportation

The Internet of Things (IoT) supports transport and logistics in many ways. It can help enhance the estimated time of arrival (ETA) for shipments in the supply chain. IoT data collected from trucks aid logistics managers to understand how drivers behave on the road. For instance, you can estimate average speeds on various routes, or how drivers navigate traffic in congested areas. It’s a supply chain technology that’s made major advancements, yet still has nearly unfathomable opportunity to evolve in the future.

Using sensor data loggers, shipping companies can also improve safety and ensure that truckers adhere to the established hours of service. Managers can instruct drivers when and where to stop and when to start driving again.

IoT applications provide insights into how a driver’s behavior is likely to affect the ETA — for instance, stopping before a big city close to rush hour could lead to the shipment enduring a traffic jam.

Social Media in Supply Chains

Some years back, companies would discourage their employees from using social media. Many are now doing the opposite, embracing it as an informative supply chain technology. Social media penetration is continually increasing. According to research, there are about 3.6 billion social media users today, who could reach 4.41 billion by 2025.

Businesses utilize social media to boost brand awareness and market their products and services. In the supply chain, the platforms can inform shippers about conditions that could impede the smooth shipping of products. Posts about accidents and harsh weather have influenced freight managers and truckers in making shipment routing decisions.

Businesses use social platforms to build a reputation via blogging and gather suggestions for improvement from customers. Distributors can communicate the location of shipments to customers awaiting delivery. If prices of commodities change, social media is an excellent tool to update a massive audience, including international consumers. A universally accessible platform that enables communication and information sharing is increasingly being leveraged by logistics teams to get ahead of potential delays.

RFID Tags

Another groundbreaking supply chain technology that remains underutilized is asset tracking with RFID tags. These devices enhance the visibility of materials and products in the supply chain. Typically, you place RFID tags on the asset you wish to track. You can then locate it using a reader, which can communicate with the tag without a direct line of sight, such as a barcode scanner requires.

The RFID Supply Chain

RFID supply chain technology is useful in inventory management. Warehouse supervisors can reduce loss and maintain control of inventory location by embedding RFID tags on products and fitting scanners at exit points. When integrated with the enterprise resource planning (ERP) system, RFID tags enable logistics data collection to optimize not just the warehouse, but the entire supply chain.

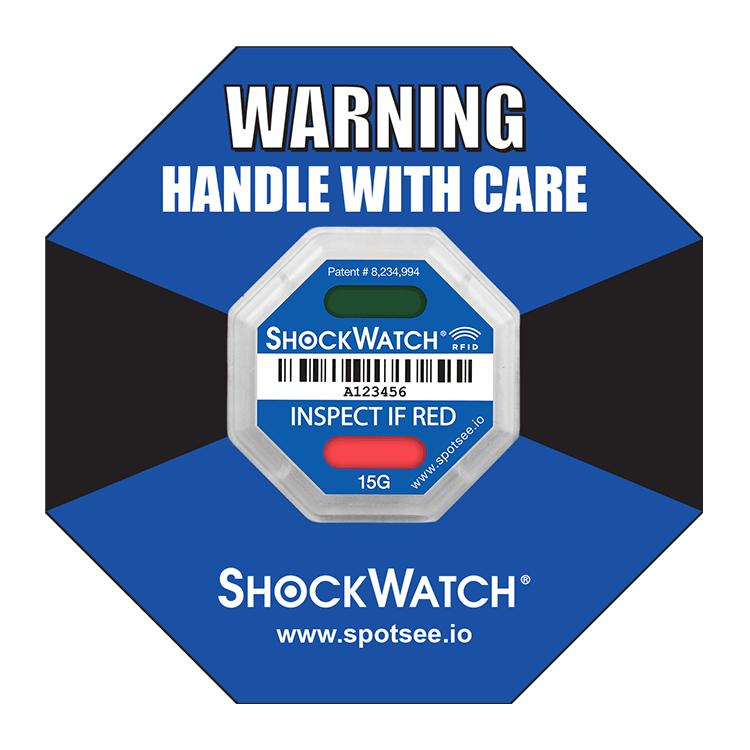

SpotSee’s ShockWatch RFID does just that. Combining an impact indicator with an RFID tag, the ShockWatch RFID gives logistics managers not only a view of whether their assets are in the right place, but also if they could be damaged. The impact monitor records a shock beyond a preset threshold, and communicates this information via RFID when scanned.

These indicators can detect anomalies in logistics that can damage products before reaching end-users. Triggers of product degradation from impact can then be identified and investigated, allowing more accountability in the supply chain — and less damage.

Not to mention, ShockWatch RFID can add to other supply chain technologies — integrated with warehouse robotics or paired with transportation data, it takes already innovative technologies to a new level of connectivity with low effort and cost.

Other Connected Monitors

While ShockWatch RFID is the breakout star of the future of supply chain technology, SpotSee’s other data loggers can measure and log a variety of parameters with connected data transmission, such as cellular, satellite, and Bluetooth… For instance, SpotBot Cellular is a temperature and impact recorder. It helps logistics managers and product handlers to identify when and where an acute shock or temperature event occurred. With SpotSee Connectivity, you can view reports about incidents in real-time via cellular communication networks. You can inspect goods en route or stop a shipment that has sustained severe damage.

Optimize your Supply Chain with SpotSee

Sensors and advanced wireless communication networks enable companies to collect and transmit data about products at every supply chain checkpoint.

This visibility promotes efficiencies, improves financial performance, and streamlines supply chain interactions Consult SpotSee via the form below to learn how to optimize your supply chain with RFID and other innovative supply chain technologies.

Consult SpotSee via the form below to learn how to optimize your supply chain with RFID and other innovative supply chain technologies.