News

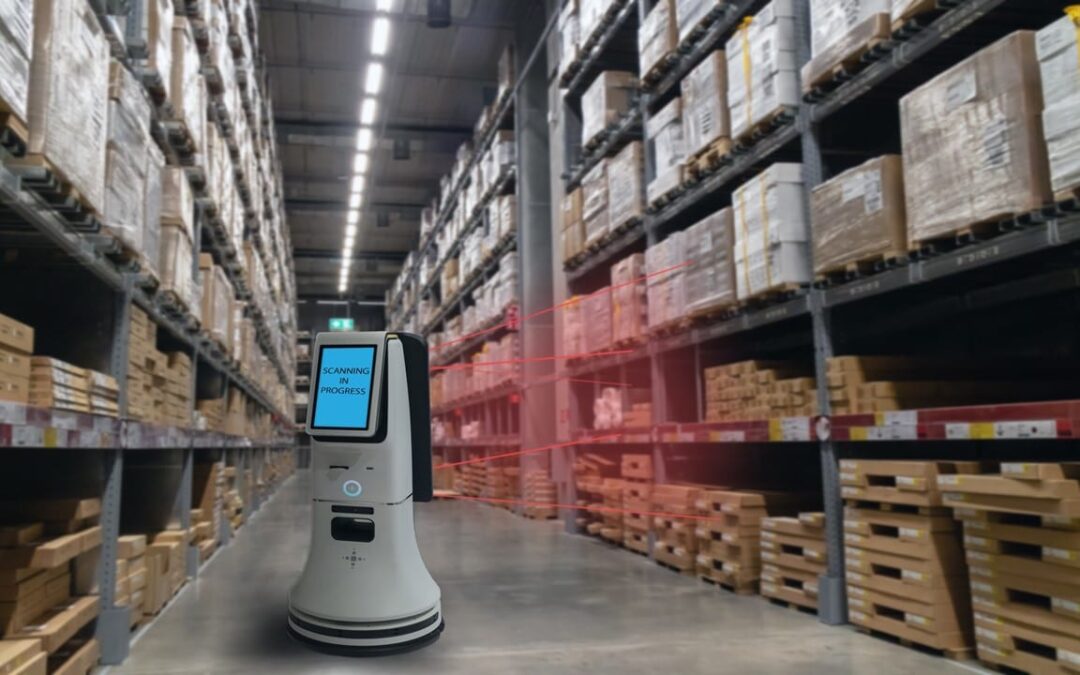

Making the Invisible, Visible: RFID Inventory Management Levels Up with Impact Indicators

The Impact of Impacts: Embrace RFID with Impact Indicators Stakeholders throughout the supply chain need to know not only where items are, but also when things go wrong. In the pharmaceutical industry, impacts and temperature variations can destroy certain therapeutic...

Thermochromic Masterbatch Pellets

Temperature sensitive thermochromic pellets containing Leuco Dyes which change from colored to colorless as temperature rises.

Irreversible Thermochromic Inks

Permanent change thermochromic ink is a high temperature activated, permanent change ink.

SpotSee Expands Vibration-Monitoring Product Family With the Launch of OpsWatch Ethernet

SpotSee®, a global leader in supply chain condition monitoring through its ShockLog®, ShockWatch®, ShockWatch® RFID, TiltWatch® and WarmMark® brands, and connectivity solutions, has expanded its vibration-monitoring product line to include OpsWatch Ethernet, an...

How RFID Impact Sensors Can Reduce Supply Chain Damage

HOME BLOG How RFID Impact Sensors Can Reduce Supply Chain DamageDamage occurs with approximately 2 percent of all shipped products - shippers, brands and retailers typically absorb this cost. SpotSee has developed the ShockWatch RFID Impact Sensor to address the...

![Reduce Shipping Damage with ShockWatch RFID [VIDEO]](https://spotsee.io/wp-content/uploads/2021/02/Reduce-shipping-damage-video-screenshot-1080x675.jpg)

Reduce Shipping Damage with ShockWatch RFID [VIDEO]

The shipping industry sees $2.3 trillion in shipping damage every year due to mishandling during transport. A bump in the road can cause big problems in your supply chain. Introducing ShockWatch RFID, a passive RFID enabled impact indicator that replaces your current...

5 Strategies for Filing More Effective Freight Claims

There are many false assumptions about freight claims. Misunderstandings about what is covered, who is liable, and how to effectively file damage claims are part of the reason approximately half of all cargo claims are denied. With the National Cargo Security Council...

Dallas Business Journal: North Texas company doubles in size to 400 employees after acquisition

Catherine Leffert of the Dallas Business Journal recently covered SpotSee's acquisition of TMC Hallcrest and LCR Hallcrest in an interview with CEO, Tony Fonk. SpotSee, a supply chain monitoring and solutions provider, acquired TMC Hallcrest and LCR Hallcrest to...

SpotSee CEO Appointed to Board of Directors for AIM

CEO and president, Tony Fonk, has been appointed to the board of directors of AIM, an association for the automatic identification industry. “It is an honor to help advance and define the changing world of IoT in real-world business conditions,” said Tony Fonk, CEO,...

SpotSee Acquires TMC Hallcrest and LCR Hallcrest

We are proud to announce that SpotSee® has acquired TMC and LCR Hallcrest, two global leaders in temperature monitoring products and indicators. The combined three businesses gives SpotSee the broadest range of temperature indicators in the industry, complementing our...

4 Ways to Embrace Supply Chain Technology of the Future, Today

Innovative technology continues to improve the way we do business, from our communications and marketing to developing and manufacturing new products. Even the way we transport goods changes continuously due to new technological advancements — but sometimes it seems...

The History of Passive RFID Tags: How Did We Get Here?

Radio Frequency Identification (RFID) is one of the quickest growing technologies. In fact, if you work in industrial manufacturing or enterprise supply chain management, you probably already have RFID implemented in some form — security, tracking, payments, and the...

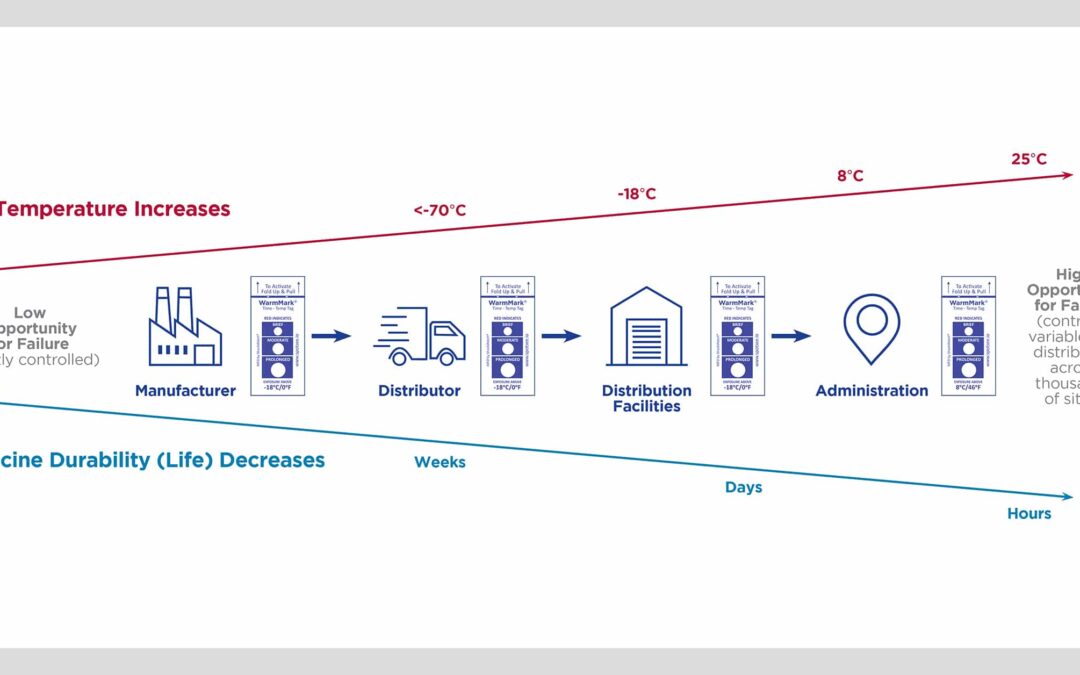

SpotSee Launches WarmMark Indicator with Additional Time and Temperature Thresholds to Match COVID-19 Vaccines

SpotSee®, a global leader in supply chain temperature indicators used to monitor test specimens in the SARS and H1N1 virus outbreaks, has introduced new temperature thresholds for its WarmMark indicators to address temperature requirements associated with the vaccine...

Types of Data Loggers — What is a Data Logger?

A data logger is an electronic device that records data (temperature, pressure, impact, humidity, etc.) at specific intervals. Discover the right data logger for you by exploring the different types and their intended applications. What is a Data Logger? A data logger...

How to Monitor Temperature in Cold Chain Logistics

s Cold chain monitoring is essential to ensure the quality and potency of sensitive products. Modern temperature tracking solutions for the cold chain logistics industry provides supply chain managers with the data and proof they need to get temperature-sensitive...

SpotSee Featured on Electronic Specifier: Transforming Supply Chain Management

In any given supply chain, there’s at least one step that requires items or products to be transported from one place to another, even if that step takes place between the supplier and the end user. Jan van Niekerk of SpotSee explains. In more complex supply chains...

Most Common Risks in Cold Chain Management

Temperature regulation is a critical facet of cold chain management. Risks abound no matter how seamless your logistics operation. Are you taking the right steps to mitigate risk in your cold supply chain? Approximately the world loses three tons of human food every...

The Necessity of RFID Asset Tracking for Manufacturing

From 2020 to 2025, the global asset tracking industry will experience a compound annual growth rate (CAGR) of 15%. After that, the sector will be worth $36.6 billion. One of the tracking methods that will contribute significantly to this growth is radio frequency...

5 Ingenious Uses of Passive RFID Tags

Passive RFID has been around for decades, but now maybe its shining, breakout moment. With its low cost and application flexibility, innovative companies around the world have found ways to put this technology to use. RFID innovation — of today and tomorrow — helps...

Avoid Supply Chain Disruptions Caused by Temperature, Impact, and More

While supply chain disruptions that cause damaged products are frustrating to customers, they can be highly disruptive and expensive for businesses. Further, substandard and spoiled goods often tarnish a brand's reputation and cause public relations nightmares. It...