Types of Data Loggers — What is a Data Logger?

A data logger is an electronic device that records data (temperature, pressure, impact, humidity, etc.) at specific intervals. Discover the right data logger for you by exploring the different types and their intended applications.

What is a Data Logger?

A data logger is an electronic device designed to record and store measurements for various conditions at specific intervals. It consists of a microprocessor, one or more sensors, and an internal data storage facility. In many cases, it can run for months or years unattended.

Measurements can include water temperature and water level, air temperature, humidity, current and voltage, variations in pressure, light intensity, soil moisture, rainfall, pulse signals, wind speed and direction, room occupancy and even the wetness of leaves.

The size and design vary depending on the device’s function – the data logger can be small enough to fit in your palm or be a stand-alone unit with multiple channels and external sensors.

Most modern data loggers can integrate with computers and smartphones via wireless networks.

Why Is a Data Logger Used?

Data loggers are useful when you need to measure and record specific parameters consistently. They can operate in harsh conditions where a human operator cannot work. With a wireless data logger, businesses can save the time and cost of sending someone to collect data in a remote location.

There are many reasons for using data loggers. For example, in the food industry, record the temperature inside food storage and transportation facilities. The loggers report when the temperature gets out of the recommended range.

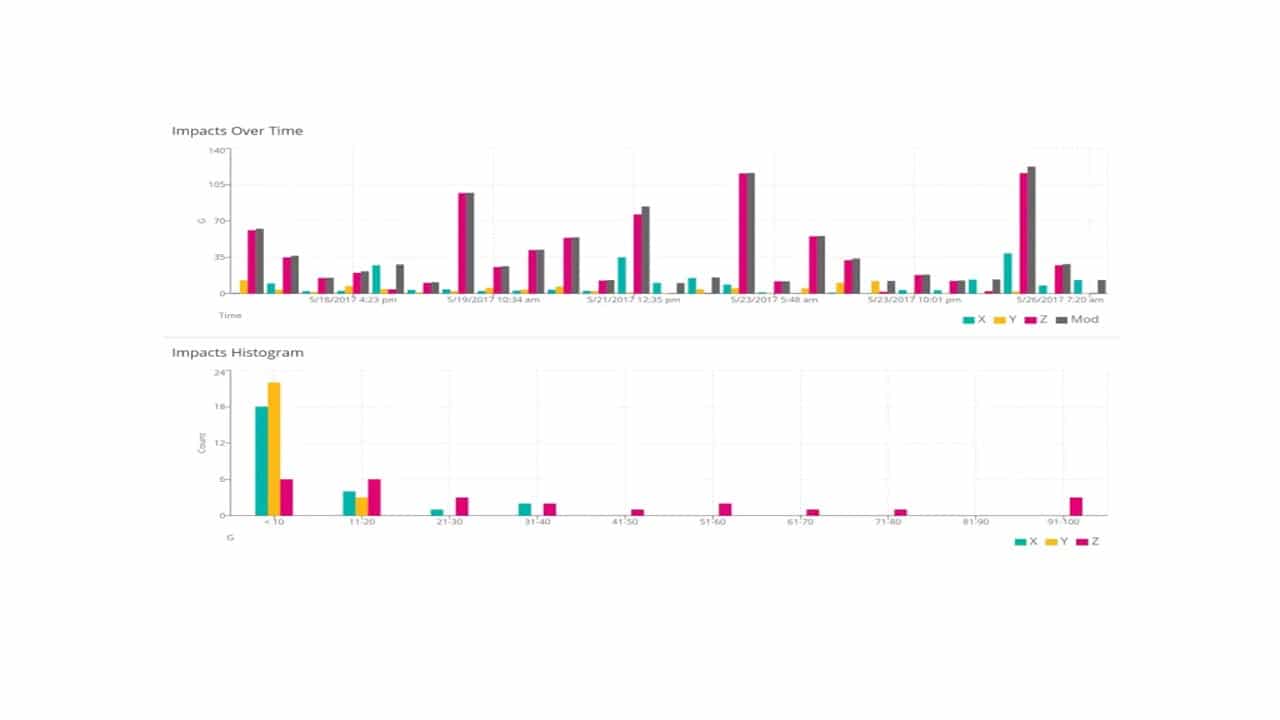

Similarly, vibration and impact data loggers record potentially damaging impacts when products are in transit.

Sophisticated models may include GPS location as well as condition information. They can log events in real-time and map them to the location where they occurred, increasing accountability in the supply chain. Managers can figure out when and where a fault happened and who was in charge.

Once deployed, the data logger can record and store each time-stamped measurement. Once the desired monitoring period is complete, the data logger downloaded in order to obtain the recorded data or the data may be viewed in cloud-based software Measurements may be displayed in graphs, which are useful for showing changes over time. Most software programs will also allow the user to view tabular data and export the recordings to a spreadsheet.

What Does a Digital Data Logger Provide?

Data from a data logger provides valuable insights that help in making informed business decisions. A digital data logger can deliver more accurate data than what manual recording can achieve. Through data analysis, you can identify bottlenecks in manufacturing and distribution. You can then correct the glitches to maximize business productivity and efficiency.

Types of Data Loggers

Data loggers are useful in settings that require consistent measuring and recording of data. Most devices can operate for months or years unattended. You can remotely measure temperature, humidity, pressure, vibration, electric current, voltage, light intensity, soil moisture, etc.

Each type of data logger collects different types of information and will be useful in specific situations. Many data loggers combine multiple parameters to offer comprehensive logging or various types of conditions.

Temperature Data Logger

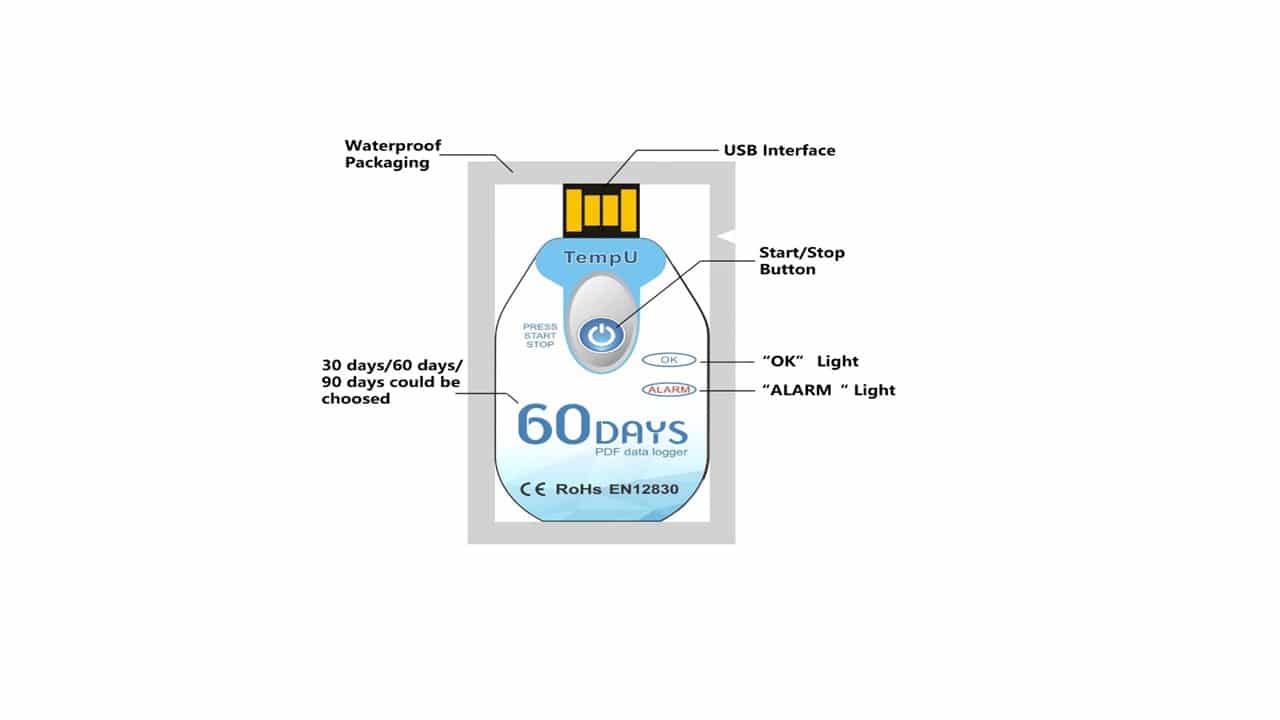

A temperature data logger monitors temperature throughout the shipping and handling stages of the chain and reports temperature-related events. With this information, logistics managers will know if their product has been compromised by unacceptable conditions.

These types of data loggers help to monitor shipments in cold chain industries. Examples include the transportation of pharmaceuticals, food and flowers, where unfavorable temperature affects the quality and safety of products.

See how to install the TempU Temperature Recorder to receive alerts when items get exposed to out-of-range temperatures.

SpotSee’s temperature data loggers include:

Connected Data Logger

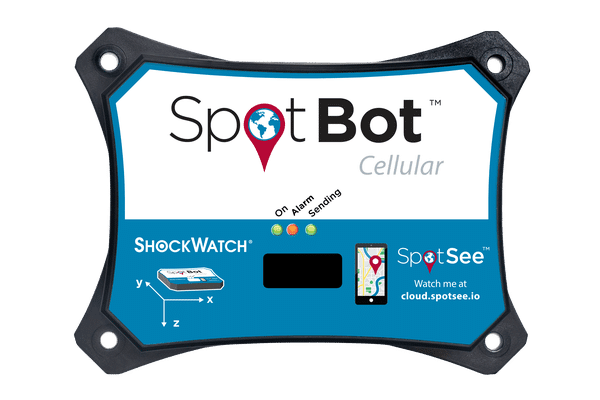

Connected data loggers offer real-time monitoring from any location via cellular networks, satellite connectivity, Bluetooth,WiFi, or RFID. Their data is typically accessed by a web-based platform, such as SpotSee Cloud. It’s important to choose the right connectivity for your business, supply chain, and products.

Connected data loggers have a configurable alarm system and instant access to recorded data. It’s one of the most flexible logging devices available, and can accommodate a variety of applications.

SpotBot Cellular reports impact and temperature incidents and where they happen. Manufactures or shippers can assess the damage and act within the shortest time.

Additional wireless data loggers from SpotSee include:

Humidity Data Loggers

Humidity data loggers measure environmental humidity levels and provide real-time alerts. They are useful in moisture-sensitive environments such as warehouses, calibration rooms, cargo ships, greenhouses, attics, and basements.

Multi-channel data loggers like SpotBot BLE track humidity alongside temperature, shock, tilt, and present data on a mobile app.

Impact Data Logger

Impact data loggers record data regarding tri-axial shock data using built-in accelerometers.

SpotSee’s ShockLog 298 is one such example. While it’s core purpose is as a shock/impact recorder, it has optional add-on modules to measure pressure — as well as temperature, humidity, and tilt/roll. It can also be connected via cellular or satellite modules for instant data access.

Vibration Data Logger

If assets or machinery are sensitive to low-frequency vibrations — or if unnatural vibrations can be a sign of impending failure — the tool for the job is a vibration data logger.

A vibration data logger can measure and record vibrations, shocks and tremors over time. The accelerometers can indicate all events that breach a preset threshold of vibrations.

OpsWatch monitors the level of vibrations of a machine during its operation. It alerts the operator when the vibrations are out of the normal range. Real-time vibration monitoring enables predictive maintenance, scheduled downtime, and a heads-up if something isn’t working right. The device enables you to inspect and diagnose issues with industrial equipment before serious problems occur.

ShockLog 298 takes a similar approach, but geared for transportation of assets or heavy machinery. If something is on the move and it’s sensitive to vibration or shock, ShockLog 298 keeps track. It provides logistics managers data to inform whether an asset may be damaged or in need of inspection.

Finding the Right Data Logger for You

With all these different types of data loggers, it can still be hard to zero in on the right solution for you, even once you understand how they differ. SpotSee categorizes data loggers by needs including the monitoring of impact, temperature, and vibration, but many track multiple parameters beyond these, such as humidity, pressure, and tilt/roll.

One way to figure out the right data logger is to explore various applications.

The best way to refine your search and find a solution that optimizes your operations and supply chain is to get in touch with a data logger expert for a consultation. Fill out the form below, and SpotSee will reach out to answer your questions about data loggers— and find the best option for you.